Share

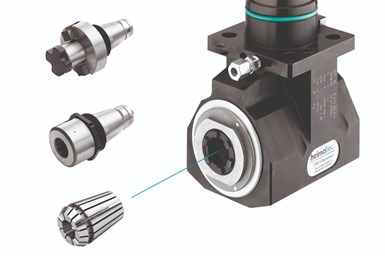

In this image, you can see the variety of toolholders that a flexible live tool can use. Having these options makes it easier for job shops to make use of different cutting tools without having to invest in several live tools.

Live tooling is well known as an excellent option for performing secondary operations on turned parts. They eliminate the losses of precision and time from moving a part to a milling machine, making turning machines much more productive. Additionally, they make finishing deep features in turned parts much easier.

According to Platinum Tooling President Preben Hansen, the variety of applications that can be performed with a machine is equally impressive. “I have seen a dozen live tools on a single turret, with that shop able to produce parts of mill-turn complexity with a single-spindle turning machine,” he says. Yet the sheer variety of available live tooling can give shops choice paralysis. “A lot of people don’t understand how many different products are available. Live tooling can be designed to handle different materials and different physical spaces, as well as different speeds and feeds.”

With all of these options, choosing the right one can be daunting. In a conversation with Hansen about the factors influencing live tooling, he offered these four questions for guiding the choice:

- Are you buying for one job or multiple? High-production shops in medical, for example, may prefer one or more specialized tools to get the best feed rate and finish on each process. However, job shops may want to go in a different direction. “A job shop looking to get into live tooling should focus on flexibility,” Hansen says. “That means buying a system that can accommodate different cutting tools for different materials and purposes.”

- How long and how fast? As with cutting tool edges, wear is the enemy of tool life in live tooling. The longer your tooling is running, the greater the wear. However, there are ways to extend the life. “If a job requires running the live tooling too long,” says Hansen, “then a speed increaser is going to be your best friend.” Speed increasers, in addition to the other benefits of increasing cutting tool speed, reduce the wear and tear on the machine tool’s turret, helping it to run longer.

- What are you cutting? Just as it defines the cutting tool needs, the material will often affect the live tool needs. “Talk with your supplier,” Hansen says. “Tell them the material you are cutting and the finish you need. That will help them to develop a system that fits your shop’s needs.” Getting the torque, rigidity and speed required is the priority.

-

Do you need through-coolant? For many more difficult materials, through-coolant is required. “Every live tool at Platinum is through-coolant capable,” Hansen says. “But it’s important that the user consider the coolant capabilities of your machine.” This can be especially important when drilling deep holes, as the constant coolant flow can flush chips away, making the drilling operation much faster.

For many jobs, especially with materials like titanium, through coolant is essential. Fortunately, most providers have live tooling with through-coolant capabilities.

Related Content

6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreRead Next

Multitasking Machining Equipment: Now the New Normal

Equipment that can turn, mill and more is quickly becoming the standard in metalworking technology. These machines can produce increasingly complex parts in a single setup yet are easier operate than ever before.

Read MoreSwiss-Types Offer Advantages Beyond Watchmaking

CNC sliding headstock lathes are becoming more popular among traditional machine shops for their multitasking capabilities, some offering B-axis milling spindles.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More