Toolholders

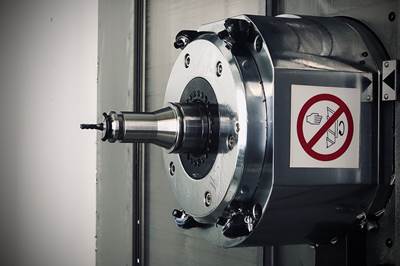

The Toolholder is the essential connection between the machining center and the cutting tool. The toolholder fits into and is secured by the machining center’s spindle, and in turn, secures the cutting tool such as a drill or end mill by clamping onto its shank. The taper of the toolholder matches the toolholder interface of the particular spindle. Toolholder tapers are often conical, including CAT and BT taper specifications. A different kind of taper, HSK, is not tapered at all, but instead includes a variety of flanges for securely locking the toolholder in place. Toolholders use different mechanisms for clamping the tool including set screw, collet, hydraulic compression and shrink-fit.

ESSENTIAL READING

VIEW ALLHow to Manage Cutting Tool Inventory in a Small Job Shop — The One-Person Shop #4

Working in short lead times means maintaining a large range of tools to be ready. What is the right way to stock and organize this investment?

WatchCutting Tool Technology Aids Lights-Out Machining Applications

These features can help improve cutting tool stability, standardize cutting performance and extend tool life, enabling shops to confidently run unattended shifts.

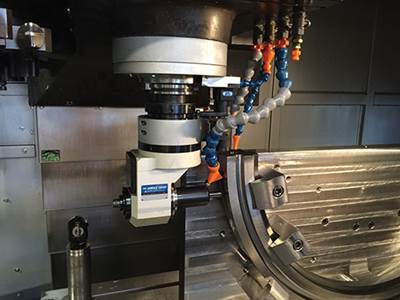

Read MoreWhat To Consider When Adding Angle Heads

Angle heads can enable a three-axis machine tool to be more versatile. That said, this shop explains that there’s more to getting started using them than simply loading them into a machine’s spindle.

Read MoreVideo Shows How to Check Toolholder Runout

Here’s a video that explains how to check the runout on a collet chuck toolholder.

Read MoreA Machinist’s Guide to Toolholder Maintenance

Techniks’ “Machinist’s Guide to Toolholder Maintenance” can be a handy reference for inexperienced machinists and shop veterans alike.

Read MoreWhy the Y?

See how Y-axis toolholders enable Swiss-type lathes to realize better chip control.

Read MoreLatest Toolholders News And Updates

Tungaloy Boring Toolholder Features Advanced Chip Evacuation

The TungBoreMini series includes an optimized chipbreaker and an advanced internal coolant supply system, which features two dedicated outlets for effective cooling and chip evacuation.

Read MoreSandvik Coromant Damping Mechanism Enhances Turning Adapters

Sandvik Coromant announces upgrades to the damping mechanism for its Silent Tools turning adapters, improving surface finish during internal turning operations at long overhangs.

Read MoreSandvik Coromant Quick-Change Toolholder Supports Small Part Machining

Sandvik Coromant’s QS Micro quick-change holding system combines simple tool changes with modularity, ideal for small part machining operations.

Read MoreRego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read MoreThrough-Coolant System Cuts Nickel-Alloy Cycle Times by 70%

Decker Machine Works recently adopted Rego-Fix’s reCool through-coolant system for ER collets, reducing the cycle times on a nickel alloy job by 70%.

Read MoreRego-Fix, Omega TMM Tool Measuring Machine Improves Tooling Accuracy

Rego-Fix has collaborated with Omega TMM to create Orion, a tool measuring machine using Rego-Fix’s PowRgrip toolholding system with Omega TMM’s presetting technology.

Read MoreFeatured Posts

Making the Most of Mixed Toolholder Assemblies

While nearly all ER systems will have cross compatibility, they’ll have small differences across manufacturers that make their implementation at the shop level not as standard.

Read MoreFive Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

WatchHow to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

Read MoreSimulation and Tooling Secure High-Value Work

Simulation software and careful attention to tooling parameters have enabled Major Tool to take on ambitious projects with its complex machinery.

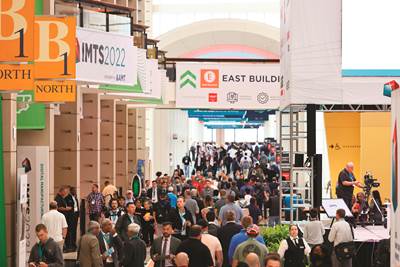

Read MoreIMTS Takeaways From the 91ÊÓƵÍøÕ¾ÎÛ Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

WatchHaimer USA Models a Streamlined Toolroom

Haimer USA is celebrating its 20th anniversary with a live demonstration of its digital toolroom. Find out more past the aluminum panther.

Read MoreFAQ: Toolholders

What is a HSK toolholder?

HSK, meanwhile, works by elastically deforming the toolholder. Fingers inside the hollow shank of the toolholder clamp the holder by pushing out. High spindle speed helps this interface, because the centrifugal force strengthens this clamping.

Source: Testing Measures Impact of Toolholder Interface Rigidity

How does a hydraulic toolholder work?

The hydraulic toolholder works by using fluid to compress an internal membrane within the holder body. The hydraulic fluid delivers uniform pressure around the membrane allowing it to compress equally around the periphery of the cutting tool. Basically, that’s how the hydraulic toolholder delivers its high concentricity specs.

Source: Why Use Hydraulic Toolholders

What is a toolholder?

The toolholder is the connection between the machining center and the cutting tool, employing clamping mechanisms such as set screws, collets, and shrink-fit.