A Look at Additive Manufacturing in Minnesota

Increasing interest in 3D printing among machine shops was particularly conspicuous during a recent visit to multiple shops in Minneapolis, Minnesota.

Share

Last December, I spent four days visiting seven CNC machine shops in and around Minneapolis, Minnesota. Something I found interesting is six of them are using 3D-printing equipment in some way.

One of those six shops is Monticello’s (UMC), which primarily serves the aerospace and medical markets. UMC purchased its 3D printer in 2014, a Stratasys Fortus, that prints parts in acrylonitrile butadiene styrene (ABS) polymer.

UMC uses its printer in various ways. During the quoting and design for manufacturability stages, it commonly 3D prints prototypes for the new job. This is, perhaps, the most common use of plastic 3D printers among machine shops. Engineering Manager Corey Fouquette says this gives UMC a better idea of how to best fixture the part on a machine, helps identify areas where cutting tool or spindle clearance might be an issue, helps determine the best way for a tool to approach a certain feature to be machined, and so on. “Some of this you can glean by examining the part’s 3D CAD model, but we often find it more beneficial to have something physical to hold and manipulate by hand,” he notes. For large aerospace parts, UMC might 3D print them at a smaller scale.

The shop also 3D prints fixtures that secure parts to be measured on its coordinate measuring machine. One example I saw was a two-piece fixture featuring a base and hinged door. Once the part is installed in the fixture base, the door is closed around it and magnets keep it shut. Because it is made from polymer and not metal, it will not mar a part’s finish. This is important because those parts are machined for a medical application in which appearance is just as important as functionality.

Plus, turnaround time to 3D print the fixture is faster than making one from metal. “We can 3D print both components of this fixture at the same time in 24 hours,” Mr. Fouquette says. “It would take upwards of a week to make this out of metal when you consider the time it would take to obtain material, machine what would be five components, then assemble them.” The only assembly required for the polymer fixture is adding a pin to connect the door to the base. The print job is paused at a certain point to add the magnets, then printing continues, securing the magnets in the polymer.

Mr. Fouquette says UMC’s printer runs nearly 24/7. That certainly was not the case early on. “Our employees pretty much ignored it at first,” he says. “However, we launched an engineering internship program about the time we purchased the printer. Although those college juniors and seniors were ‘green’ when it came to conventional machining and manufacturing approaches, they really took to the 3D printer. They were designing and printing parts within a matter of days.”

In fact, the students solved a problem the shop was having protecting certain areas of a part during grit blasting. Their idea was to 3D print molds to create rubber masks to protect the areas of the part that did not call for an abrasive surface finish.

“Our seasoned employees saw what those ‘inexperienced’ young people were doing with our 3D printer, and that spurred them to learn how to use it and how to benefit from it,” Mr. Fouquette says. “That’s the key. You have to ingrain 3D printing into your shop’s culture.”

Related Content

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreThe Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance additive manufacturing application and adoption.

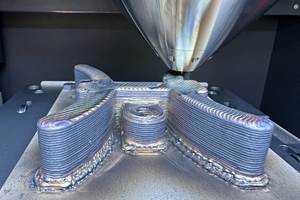

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read More