A “Shortcut” for Bladed Components

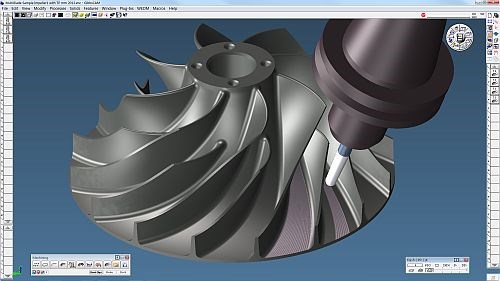

GibbsCAM offers two options designed to simplify the programming of bladed workpieces such as blisks and impellers.

Share

Industries like aerospace and automotive depend on bladed components such as impellers and blisks, but these workpieces can be complex and time-consuming to program and machine. ’ MultiBlade options for GibbsCAM provide a simplified user interface optimized for working with bladed workpieces within the GibbsCAM environment.

Two levels are available, depending on the type of work or level of specialization required. Level 1 covers workpieces with single splitters, and Level 2 can be added to support multiple splitters, sub-splitters, blade fillet machining and other advanced features.

Watch the video above, produced by Gibbs and Associates, for an overview of the MultiBlade functionality in GibbsCAM.

Related Content

-

How a Custom ERP System Drives Automation in Large-Format Machining

Part of Major Tool’s 52,000 square-foot building expansion includes the installation of this new Waldrich Coburg Taurus 30 vertical machining center.

-

Sandvik Coromant Inserts Provide Stable Turning of Aerospace Components

The new insert grades GC1205 and GC1210 cover a large application area within last-stage machining and intermediate-stage machining when turning aerospace engine components.

-

Function Over Form

While the metalworking industry includes a wide variety of machine shops, it is worthwhile remembering that the differences obscure a key commonality: they all run on human ingenuity.

.jpg;width=70;height=70;mode=crop)