Automatic Pallet Systems Increase Production And Quality

These pallet changer systems not only improved this tooling manufacturer's labor situation, but they managed to increase their production as much as 600 percent on some of its indexable cutting tool products.

Share

Dorian Tool (East Bernard, Texas) is a leading manufacturer of knurling tools and indexable tooling for manual and CNC machines used by aerospace, automotive, medical and other metalworking industries. A little over a year ago, President Enrico R. Giannetti began looking for ways to increase the efficiency of the company's machining operations. Mr. Giannetti's natural first thought was to hire more machine operators, but the robust labor market made it difficult to find qualified operators in his area. After some research Dorian turned to automation to solve its productivity problem.

Dorian Tool was driven to automate its manufacturing and found a solution by purchasing four Midaco (Elk Grove Village, Illinois) pallet changer systems. Midaco's pallet changer systems not only eliminated Dorian's labor situation, but they managed to increase Dorian's production as much as 600 percent on some of its indexable cutting tool products.

"It was much easier to automate our machines than it was to find good people," Mr. Giannetti says, "The labor market is so saturated, and it's difficult to get good people." Mr. Giannetti had been looking around and did a lot of traveling, enabling him to review better ways to machine Dorian's parts. His research convinced him to purchase two A4020SD automatic pallet changers after great difficulty finding qualified people.

Upon installation of the first two pallet changers, Dorian noticed a significant increase in production. Mr. Giannetti was so pleased with the initial performance of the pallet changers that he bought two more of the A4020SD model and one A5025SD automatic pallet system. Within their first year of production, the pallet changers had helped Dorian increase production up to 600 percent on some of its products. Mr. Giannetti also points out that the pallet changers have enabled the company to improve the overall quality of its products.

"The pallet changers are not only cutting costs in manufacturing but are also helping us to improve and monitor quality," Mr. Giannetti says, "We are able to set up a machine to run multiple parts, allowing the (machine) operator to spend more time checking quality rather than changing part after part."

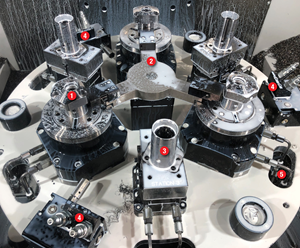

Dorian uses the pallet changers to change parts on its vertical machining centers while the machine is running. The pallet changers replaced the machining centers' fourth and fifth axis rotary tables that were used to manipulate parts for multiple side machining. Using the rotary tables, the machining centers could only machine one part at a time. The pallet changers enable machine operators to load multiple parts onto a machine.

"It's great! Now we can load one group of parts while another group of parts is being machined," Mr. Giannetti says.

According to Mr. Giannetti, the pallet changers enable Dorian's machining centers to operate faster, easier and with less stress. Additionally, the large pallets give operators greater area on their machines to place more parts, which contributes to longer cycle times. "Now we have one operator running two machines. Before the pallet changer, we had one operator per machine," says Mr. Giannetti.

"The pallet changer's receiver is bolted onto the top of the machine's T-Slot table. With the pallet changer in place, the plain cast-aluminum pallets allow us more holding area for parts and provide the same rigidity as if we were bolting the parts directly to the machine's table," Mr. Giannetti says. The pallet changers provide Dorian with additional flexibility as each changer allows pallets to be interchanged with other systems of the same series with repeatability accuracy of ±0.0001 inch.

"The positive results we have achieved with the Midaco pallet changers have convinced us to install more pallet changers," Mr. Giannetti says, "As we constantly search to find machine operators that match the company's strict criteria for quality, the pallet changers help maintain high shop productivity.

"I'm very happy with the Midaco pallet changers," Mr. Giannetti says.

Related Content

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreSMW Autoblok's Workholding System Removes Obstacles

Eastec 2023: MillTec makes it is easier to carry out complex operations with five-sided access to the part.

Read MoreRead Next

Machine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read More