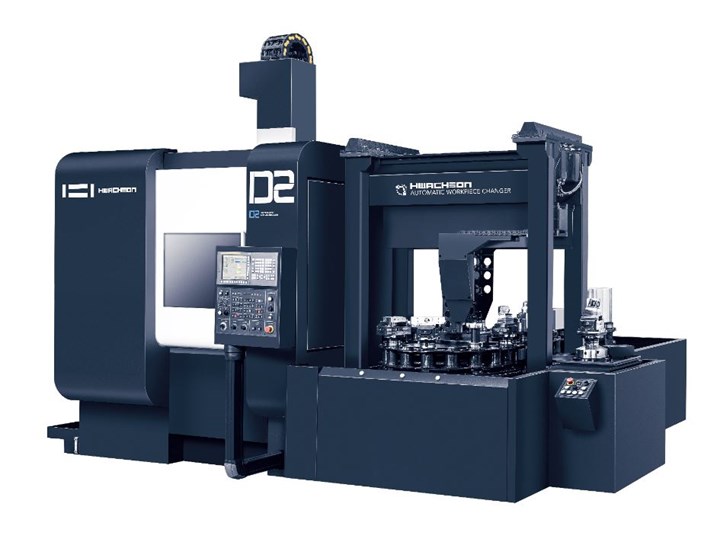

Automation Solutions featuring Hwacheon's D2-5AX and Automatic Workpiece Changer

In this digital demo, Jeong Hoon highlights many of the benefits the D2-5AX provides when machining complex shapes and parts. You will also learn how to maximize productivity during this inside look into Hwacheon’s automatic workpiece changer, the perfect solution for mass production.

Share

The D2-5AX is Hwacheon’s best-selling 5-axis machining center and offers a variety of spindle selections up to 24,000rpm that can be customized based on your specific machining needs. In addition to customization, the Hwacheon automatic workpiece changer is an excellent solution for mass production. Allowing you to dramatically reduce set up times, the automatic workpiece changer is cost effective and efficient. The work set up station on the automatic workpiece changer is also separately configured from the machine operating area, allowing you to safely work even while the machine is in motion. Equipped with Hwacheon’s very own software package, including a scheduling system, your production team has the ability to manage multiple projects at once, increasing productivity.

For more information on this and other Hwacheon products, visit and follow them online on and .