Centerline Issues for Turning Inserts

Tooling experts Mike Fagan and David Grant suspect that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is their effort to clear up some of the misunderstanding.

Share

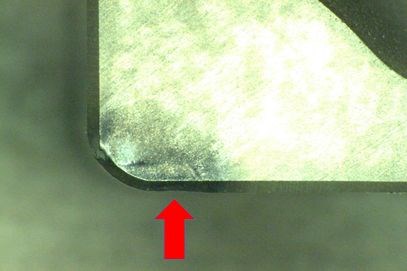

Photos of sample inserts such as this one illustrate wear patterns that help diagnose cutting tool misalignments in turning.

Tooling expert Mike Fagan suspects that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is his effort to clear up some of the misunderstanding.

It covers signs of misalignment and suggests ways to fix problems, with additional tips and advice to improve turning operations. To find the paper, click here.

Related Content

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.