EDM Brings Capacity, Capability to New Heights

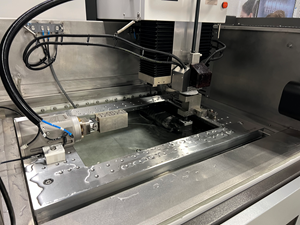

A wire EDM’s increased Z-axis capacity enabled this shop to take on larger parts.

Share

Related Content

Wall Colmonoy Acquires New Wire EDM From Sodick

The company will use the new wire EDM machine to increase capacity, improve cycle times, achieve tighter tolerances and improve surface finishes.

Read MoreHybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Read MoreEDM Network Wire EDM Features Four-Axis Cutting

The EDMMax 434W fast-wire EDM includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts.

Read MoreMC Machinery EDM Offerings Provide Optimized Performance

MC Machinery’s Mitsubishi SG12 and MV2400 EDMs provide ergonomic and efficient operations.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More