Five Design for Manufacturability Tips for Designers

Leading machine shops offer design for manufacturability (DFM) advice to customers to reduce machining cost and lead time. Here are five examples.

Share

Responses from our 2016 Top Shops benchmarking survey show that leading shops are more likely to offer design for manufacturability (DFM) advice to their customers than poorer-performing shops. Suggesting ways to simplify machining work can lead to lower part costs and faster delivery times. , which has in-house machining and additive manufacturing capacity and maintains a , is an example of a company that does this.

Here, the Xometry Project Engineering Team offers five tips that a shop might suggest to a product designer to streamline part manufacturability:

1. Avoid thin, vertical walls. In general, thin walls are tough to handle. However, they become more of a burden when they are oriented vertically (or perpendicular to the machine’s work table). Walls that are less than 0.0625-inch thick are likely to deflect during machining and result in tool chatter that can leave behind unappealing scars and surface blemishes. For high-quality surface finishes, wall thicknesses should be 0.0625-inch thick or greater.

2. Avoid small/tightly packed features at deep depths. The deeper the pocket, the longer the run time. Maximum tool length-to-diameter ratios should not exceed 6:1 (for example, a 0.5-inch end mill cutting 3 inches deep). Tight corners or small features at the bottom of the cavity are very tough to mill. Tools can often be custom ordered or ground back to achieve longer depths but that significantly increases machine time and part cost.

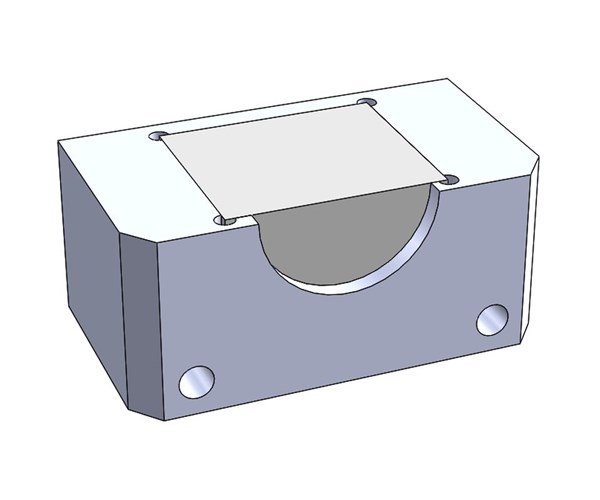

3. Design around sharp internal corners. In some cases, an assembly might require sharp internal corners. This can be accommodated without resorting to costly EDM operations. One method is to “mouse-ear” or “dog-bone” the corners as shown in the image above. This will result in a small bubble of removed material where the corner used to be that, if acceptable, will enable the mating components to fit.

4. Mind tapping depths. Tapping depths follow even stricter guidelines than traditional drilling or milling. Taps are very hard to thread consistently at aspect ratios greater than 2.5:1. If a 1/4-20 UNC thread must extend through the depth of a 1-inch plate, consider including some clearance to minimize thread engagement.

5. Consider using stand-offs or mating parts. Although it’s appealing to create a part from one piece of material, production might be more cost-effective to design it in multiple pieces. For a plate that is 0.0625-inch thick, but requires clearance for positioning additional assembly components, consider using stand-offs in lieu of machining the posts from a much larger stock size. This can save material and machining time.

Related Content

-

6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.