How Machine Tools Can Save Energy

It starts with energy-efficient designs of the servo and spindle systems. This article introduces useful concepts such as the difference between direct and indirect energy consumption.

Share

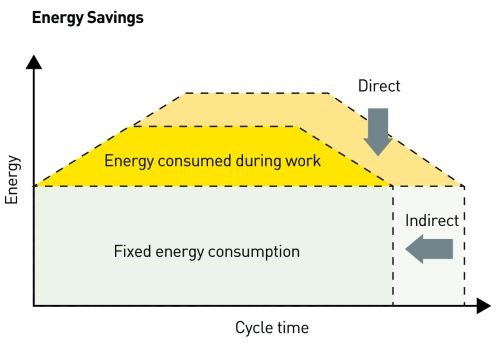

Energy usage is becoming a more important factor in determining the overall efficiency of automation systems, including CNC machine tools. Conserving energy cuts costs and protects the environment. An article by Paul Webster, engineering manager at FANUC FA America, explores the topic and focuses on the value of modern electrical motor design for CNC machine tools, injection machines and other automated production equipment. “Energy Saving Designs in Factory Automation Equipment” also introduces a number of key concepts in energy consumption and efficiency strategies.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.