Interrupted Turning Operation Cuts Cost With 10-Sided Insert

Using a robust 10-sided insert from Tungaloy, this oil-industry remanufacturer was able to reduce the number of inserts used in interrupted turning operations.

Share

In the wake of the Deepwater Horizon oil rig disaster in 2010, the United States imposed many new regulations on deep-ocean drilling that necessitated the regular replacement of blowout preventers (BOPs), which are designed to prevent future spills. To reduce the cost, oil companies turn to remanufacturers for getting used BOPs back up to specification. One such remanufacturer is (NOV), an international manufacturing company dedicated to the oil industry.

To bring a BOP back up to spec, the company welds it with Inconel, then machines the seams back down. To machine off the excess material, the company performs an interrupted turning operation, slowly lowering the cutting tool to the workpiece and cutting away the irregular Inconel seam.

Unfortunately, as the cutting tool engages the seam, it undergoes tremendous strains from constantly disengaging and reengaging with the seam. The most strenuous part of a machining operation for a cutting tool is the moment it makes contact with a part, which makes interrupted turning especially damaging for cutting tools. What this meant in practical terms for NOV was a lot of damaged inserts.

According to the company, the variability of the seams and the interrupted passes meant that each workpiece would chew through five to 10 inserts, increasing both cost and machining times. Additionally, the variability in the use of inserts made planning more difficult. NOV needed a way to extend the life of its inserts, and it eventually turned to Tungaloy.

A Robust Roughing Insert

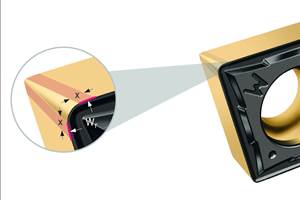

Tungaloy has developed a 10-edged tungsten carbide insert called the TurnTen-Feed, which is designed for durability and depth of cut in medium to heavy turning and roughing operations. The double-sided pentagonal insert has rounded edges with MNW-style chipbreaking protrusions in addition to a flat wiper along each cutting edge to improve surface quality, even at higher feed rates. It also uses dovetail clamping to improve stability and rigidity.

According to Tungaloy Sales Engineer Greg Davis, the cutter’s features enable it to make deep cuts in strong materials without losing durability or precision. “The insert has the strength of a round cutter, and the 10 edges provide extended tool life,” he says. Additionally, the cutter also uses its entire edge, rather than just a corner. This feature spreads the cutting forces out across the insert rather than concentrating it as a single point, improving durability and increasing the potential feed rate.

The company sells two different holders for the insert. One is a high-feed (HF) holder with a high feed rate and a 22.5-degree approach angle that is capable of feed rates as high as 0.079 inch per revolution. The other has a 48.5-degree approach angle to increase the depth of cut to as high as 0.276 inch (7 mm) per pass.

Simple Changes, Dramatic Results

The insert drew the attention of NOV due to its promise of high durability thanks to its particular thickness and dovetail clamping. This combination of resilience and rigidity come together to improve the insert’s lifespan.

According to NOV, the number of inserts the company went through on a single BOP fell from five to 10 per part to only one or two per part. This led to a 70% savings in the cost of inserts alone. With the time saved in reducing the number of tool changes, the company saved even more.

The new inserts also improved the machining process. Before switching to the TurnTen-Feed, NOV was able to reach a feed rate of 0.014 inch per revolution, but with the new inserts it was able to reach 0.03 inch per revolution. Additionally, the company was able to more than double its feed rate while maintaining precision at 0.200 inch.

This simple switch to a more robust insert had a dramatic effect on the BOP remanufacturing operation. Not only was NOV able to save time and money by reducing tool changes and improving feed rates; it was also able to improve its order planning as the range of cutters it went through shrank. Improving a shop’s output often means making simple process changes where they are needed most.

Related Content

Tungaloy Modular Turning System Provides High Repeatability

The ModuMiniTurn tool system incorporates a specialized coupling mechanism between the modular head and tool shank.

Read MoreWalter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.

Read MoreNorton | Saint Gobain Abrasives' Wheels Increase Metal Removal

The Norton Winter Paradigm Plus Diamond and Winter G-Force Plus Next Generation Diamond Wheels expand the company’s grinding wheel options.

Read MoreTungaloy Grooving Toolholders Provide Highly Stable Machining

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Read MoreRead Next

Add Punch Tapping to the List of Thread-Machining Options

Emuge has introduced the Punch Tap, a new class of tool for rapidly threading holes in aluminum.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More