Just don’t Call it Vibration

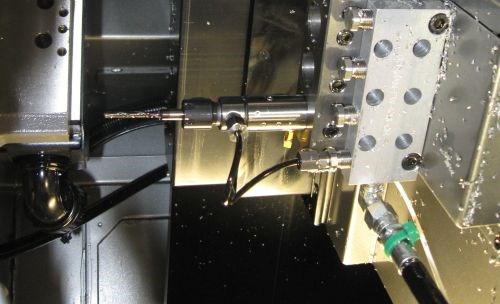

The device for rapid peck cycles holds the drill like a toolholder.

Share

The device for rapid peck cycles holds the drill like a toolholder.

I found what seemed to be a genuinely new metalworking technology when I recently visited M4 Sciences in West Lafayette, Indiana. The company’s Modulation Assisted Machining gives the drill a rapid peck cycle. The drill doesn’t move out and in every few seconds like in a typical drilling peck cycle, but instead moves out and in as rapidly as hundreds of times per second. Broken chips flow smoothly out of the hole, and cycle time and hole quality can both improve, as this video shows. The technology applies to center drilling on Swiss-types and other small lathes.

In my conversation with the developers of the technology, I kept referring to the way the device “vibrates” the tool. They were quick to correct me. In a machining context, “vibration” is generally bad. Vibration is unintended cyclic motion—motion that impedes the cut. By contrast, the motion of this device facilitates the cut. Indeed, the motion is as controlled and intended as the motion of any programmed peck cycle. It’s just that in the case of the modulated machining, performing the peck motion very frequently and very fast takes peck drilling to an entirely different level.

Related Content

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.