Laser Marking Basics

Learn about the various marking processes that lasers can perform.

Share

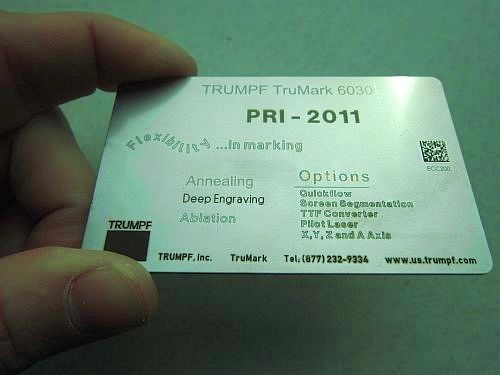

I picked up this sample at the Performance Racing Industry show. It shows the various types of marking processes that a Trumpf 6030 laser can perform.

To color plastics, the laser beam heats the surface locally, which causes some materials to become darker and others lighter in color depending on the material composition. In blackening, soot particles are generated that show the inscription in dark letters on lighter-colored plastic. To make dark plastics white, foamed marking is used whereby the laser beam melts the workpiece material locally. Small gas bubbles form in the molten material that increase the material’s volume creating foam. The processed area appears much brighter than the surrounding material and, in some cases, the marking is raised above the surface of the workpiece.

Related Content

-

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

-

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

-

4 Manufacturing Trends That Cannot Be Ignored

The next five years will present their own unique set of challenges, and shops can alleviate them by embracing these technologies and trends.