Laying Composites Fiber—Digitally

The most recent release of Spring Technologies’ NCSIMUL software can simulate the laying of fiber ribbon with NC machines.

Share

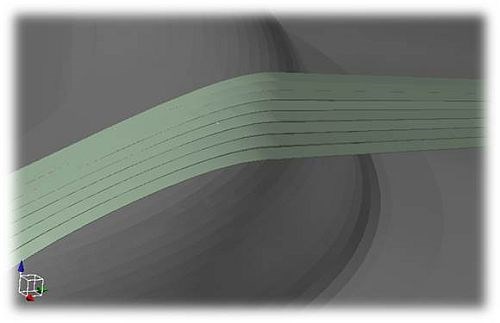

NCSIMUL Machine 9.1 takes into consideration the 3D form of fiber ribbon

to simulate building up a workpiece.

Spring Technologies’ NCSIMUL Machine software is typically thought of as a means to simulate the path of a CNC cutting tool—used to remove material from a workpiece in conventional machining. However, the most recent release of this program is capable of simulating the addition of material. NCSIMUL Machine version 9.1 includes a “Composite” option that dynamically simulates laying fiber ribbon with NC machines. The option can alert users to composites-specific problems such as deviation caused by steering angle errors or the twisting of taut fibers. Learn more on the company’s website.

Of course, machining composites is more in our readership’s wheelhouse. Here are four articles that address the challenges machining those tough materials:

1. Setting the Stage for Sizeable Composites Work

2. Composites Machining for the F-35

3. Getting New Business with Big Machines

4. An Alternate Micromachining Process for Composites

Related Content

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.jpg;width=70;height=70;mode=crop)