Share

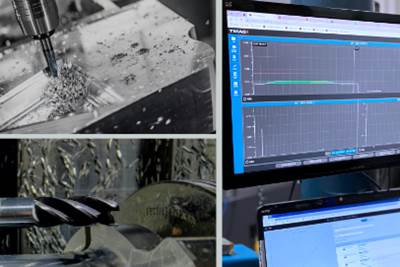

Wolfram Manufacturing’s use of machine monitoring data from its own program, OnTakt, is evident from the equipment on its floor. The data showed chip management was causing a bottleneck, so the shop now has more chip conveyors than machine tools. Photos provided by Wolfram Manufacturing.

Wolfram Manufacturing started in 2011 as a machine shop in Austin, Texas. By 2024, the company has added “integrator” and “software developer” to its portfolio — it implements Caron Engineering products at manufacturers in the South and Southwest regions of the United States and now offers its own production management and machine monitoring software, called .

All three business segments are interconnected, supporting each other on Wolfram’s quest for closed-loop manufacturing. “It’s like grabbing hold of a rocket,” says Nathan Byman, president of Wolfram Manufacturing. “We get better, and our products and services get better.”

The company recently held an open house to celebrate its move into a larger facility that will benefit all three of its divisions, with space for more machines, more staff and an area to showcase the software products it sells, integrates and supports. The event included guided tours of the shop, along with exhibitors and presentations from partners on topics including tooling and automation.

Wolfram has been so successful with using Caron Engineering’s products in its own shop that it became an integrator and production technology center for Caron, expanding its business beyond machining.

“More Than Keeping Score”

Automation has proved to be critical to Wolfram’s success, particularly Caron Engineering’s products. It has TMAC, Caron’s adaptive tool monitoring program, on all of its machine tools, and has built several custom applications using MiConnect, including one that notifies operators when chip bins are full, and another that integrates RFID chips on the tooling for all machines.

The last application is part of Wolfram’s plan to automate tool loading and unloading with robots, along with an Omega tool presetter that can read RFID chips. The shop’s extensive use of these programs led to it becoming an integrator for Caron Engineering in 2015. Wolfram became a Production Technology Center for Caron Engineering in 2022, showcasing its use of the products to Caron Engineering customers in the region.

Machine monitoring is also a key component in Wolfram’s operation. The company began offering its OnTakt software product for machine monitoring and production management in 2022. Later that year, to complement OnTakt with more communication and analytic capabilities.

Wolfram’s three business units are all interconnected, ultimately helping the company achieve its goal of closed-loop manufacturing. This Omega tool presetter will play a role in the company’s quest for automating tooling loading and unloading with robots.

In regards to its own use of machine tool data, Byman says, “Machine monitoring is more than keeping score.” The team has used many insights from this data to improve operations. For example, Byman pointed out that the shop floor has more chip conveyors than machines. This is because Wolfram determined, based on its machine monitoring data, that its chip conveyors were causing downtime and calculated that if it added more, they’d pay for themselves quickly.

Related Content

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

Caron Engineering Systems Integrator Expands Territory to West Coast

Wolfram Manufacturing, an integrator of Caron Engineering Systems, acquires new distribution areas.

Read MoreCaron Engineering, Wolfram to Open Production Tech Center

Production Technology Center to open at Wolfram’s Austin, Texas location that will showcase Caron lights-out machining solutions.

Read MoreManufacturing Association Aids Shop’s Pivot to Ventilator Parts

After reaching out to the Austin Regional Manufacturers Association, a shop that typically serves oil and gas and heavy industry was able to quickly fill an order for ventilator parts.

Read More