Moldmaker Speeds Production with 3D-Printed Fixtures

A 3D printer helps this mold manufacturer save time and money in making custom fixturing.

Share

Mold manufacturer prides itself on working closely with customers to prototype and help refine the design of products before building the molds. Its Maker Gear M2 3D printer helps with this service, enabling the shop to quickly turn out prototypes. But the printer is also used in production. 3D-printed custom supports and workholding fixtures have saved the shop money and time in turning around its moldmaking work.

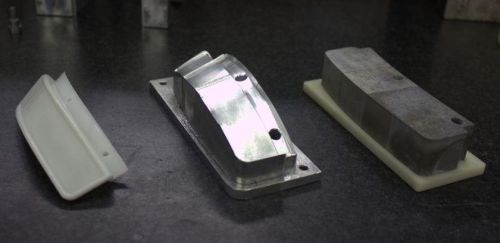

The image above depicts one example. The plastic injection-molded part on the left is a component for a feed auger, used to push product up and out of a chute. The piece was designed to be held in place with two stainless steel rivets pressed into the two holes and attached to the auger via rare earth magnets.

The angle of the holes combined with the curve of the part made it necessary to build the B side of the injection mold in three parts, so that they could be removed without damaging the features. Holding this section of the mold for machining in the shop’s sinker EDM proved to be a challenge; aside from consisting of multiple pieces, this portion of the mold offered no parallel sides for clamping. A custom 3D-printed fixture (visible on the right) held the parts together and provided the necessary straight edges.

Read more about how .

Related Content

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

.jpg;width=70;height=70;mode=crop)