New Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of 91ÊÓƵÍøÕ¾ÎÛ, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

Share

Kurt Manufacturing’s story started when it was founded in 1946 in Minneapolis. The company oversees four separate divisions of manufacturing — Kurt Machining, Kurt Die Casting, Kurt Workholding and Kurt Hydraulics. Within these four divisions, Kurt seeks to provide clients with high-quality products and solutions utilizing the company’s experience and expertise.

Brent Donaldson, executive editor of 91ÊÓƵÍøÕ¾ÎÛ, recently sat down with Paul Carlsen, vice president of corporate marketing at Kurt Manufacturing, to discuss Kurt’s booth at IMTS this year. In the meantime, MMS discovered more about Kurt’s complete branding overhaul and what the future looks like for the company.

Brent Donaldson, 91ÊÓƵÍøÕ¾ÎÛ: What should attendees know about what Kurt is doing at IMTS this year?

Paul Carlsen, Kurt Manufacturing: Certainly, we have a new display this year. We've got a whole new booth design, much more focused on automation products than in the past.

BD: Okay, let's dissect that a little bit. Can you talk about any new elements of the design itself?

PC: In the past, we've normally had our standard products out on the show floor. Not a whole lot of moving parts, I guess, would be a good way to put it. This year, we've got two robots in the booth, one a larger Fanuc robot. It’s a 12-by-12-foot table, showing our products that work in an automation-type environment. So, think air vises and hydraulic vises. That larger robot is moving material in and out of hydraulic and air vises. There's a hydraulic pump system that'll be showcased alongside it, showing our other hydraulic solutions like our hydraulic hose and couplings. We also have a new robotic end effector gripper that is on both robots.

BD: What’s the other robot being featured?

PC: The other robot we have is a smaller cobot, and its primary focus is showing off that gripper. The RV 36 gripper has some unique feature sets to it.

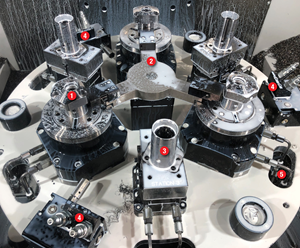

The Kurt Workholding RV36 Gripper, being shown in action by both robots featured at Kurt’s booth at IMTS 2022.

Photo Credit: Kurt Manufacturing

BD: So, this year, it’s all about automation?

PC: No, actually. Along the back wall of the booth, we have all of our high-volume standard products. We've got our new five axis workholding line as well—that’ll be another big focus. It'll be six new main skews for that product line along with a bunch of accessories that work with them.

BD: What was the impetus for this booth redesign?

PC: Kurt has a pretty diverse set of divisions, including Workholding, Hydraulics and then Kurt Machining. We also have our Die Casting division. So, yeah, diverse, but all centered around the machining world. We went through a complete corporate branding overhaul between two and three years ago, and this is our first real opportunity to show off our new branding and marketing direction. A lot of the divisions were running a bit independently, so we consolidated all of that under the corporate umbrella. We’re putting a lot toward the booth because this is really our first opportunity to show this off. It’s a big change from what we’ve done in the past.

BD: With everything that you've talked about right now, is there any sort of background information about why you're highlighting these products?

PC: Like everyone, we've seen the investments in automation as the industry continues to change, and people are harder to find. So, we're doing everything we can to help machine shops with their labor and their labor problems, and get products out there that fill those needs.

Related Content

Prioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreFixtureworks Pneumatic Clamp Fasteners Reduce Setup Time

The product lineup includes ball-lock pneumatic fasteners, ID holding, pin holding single- and double-acting pneumatic clamping fasteners.

Read MoreRead Next

Machine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More