One Small Step for Metals, One Giant Leap for AM

Eliminating support structures for metal parts expands pathways to profitable AM.

Share

For most manufacturing processes, the more complex the part, the more expensive it will be to produce. This is not a surprise. Machining a complex part can require a combination of set-ups, fixtures, jigs, tooling and so on, which all drive up cost. Similar logic applies to injection molding: The more complex the part, the more expensive the tooling, the more expensive the part. Same goes for casting, forging, stamping and pretty much every manufacturing process we currently have at our disposal.

With additive manufacturing (AM), “the data is the tooling,” as Patrick Dunne, vice president of advanced applications at 3D Systems, eloquently said in one of his LinkedIn posts last year. Manipulating “the data” to change “the tooling” and produce a different AM part is relatively easy compared to having to remake fixtures, jigs and other (physical) tooling for conventional manufacturing. Because it is so easy by comparison, the cost is negligible, and by extension, the cost of changing the “tooling” for making complex parts is essentially zero. Consequently, it is easy to see why many tout “free complexity” when it comes to AM, finally enabling “economies of one.”

While the logic makes sense and has driven much of the hype behind AM, the bane for most metal AM processes, particularly laser powder bed fusion (L-PBF), has been support structures. They have been a necessary evil since the process was invented, and they are one of the quickest ways to kill a compelling business case for AM.

Supports are the “scrap” of metal AM, and scrap is bad for any manufacturing process. It is something manufacturing engineers work hard to reduce and eliminate with conventional processes, and the same is true with AM. Supports increase material consumption, which adds cost; increases build time, which adds more cost; and increases post-processing time, which also adds cost. Supports are a big cost multiplier that work against us, not for us.

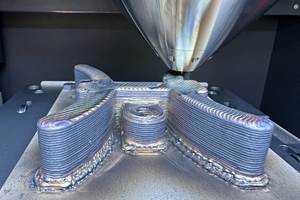

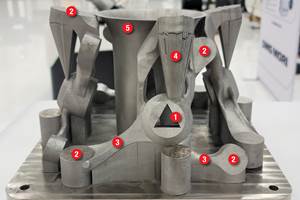

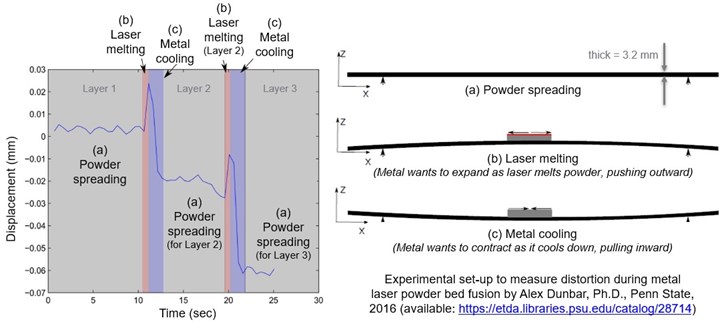

The term “supports” is actually a misnomer. Supports do not actually support the overhanging or cantilevered features on a part, as the name implies. In reality, they help anchor such features down to the build plate (or to another feature in the part) to ensure that these features do not warp or distort during the build. This warping or distortion is usually upward (in the +z direction), and, with layers as thin as 20-40 microns, it does not take a lot of upward motion before collision with a recoater blade may occur — just ask any L-PBF technician or machine operator and they will have plenty of stories to share ().

Figure 1. Experimental validation of warping and distortion that results from repeated heating and cooling during metal laser powder bed fusion (adapted from , Penn State, 2016)

Warping and distortion results from the residual stresses that accumulate during the build. The constant heating and cooling (thermal cycling) causes regions in the part to expand and contract (see Figure 1), which induces residual stresses in the metal AM part. The same thing can happen during welding, which is why joints are stress-relieved after welding. Again, no surprises here, and while countless methods, tools and algorithms exist to try and avoid overhanging structures when designing a part, supports remain inherent to L-PBF.

Velo3D and now SLM Solutions have fundamentally changed the game for L-PBF, though, by eliminating the need for supports with their SupportFree and Free Float technology, respectively. This has always been within the realm of the possible. It simply required a lot of time and energy (and money) to perfect the algorithms and software needed to analyze every feature on a part, identify the downward facing surfaces on each of these features and compute the appropriate process parameter settings for the laser scan pattern based on the angle of inclination for each surface on each feature of each layer for each part. Piece of cake, right?

Velo3D was among the first AM original equipment manufacturers (OEMs) to offer this, and it was great to see it named as one of Most Innovative Manufacturing Companies in Fast Company — a possible first for an AM OEM. Nonetheless, what I did not fully appreciate until I was speaking with Mike Rogerson last month was how eliminating supports from the majority of metal parts completely changes the economics for manufacturing existing parts, as I have railed against time and again.

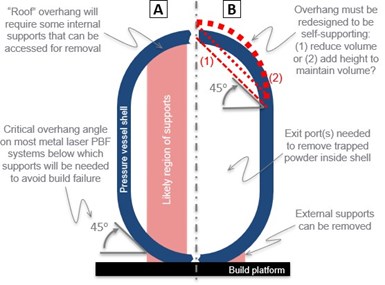

Figure 2. The challenges of eliminating supports for AM are apparent in attempts to make a pressure vessel using laser powder bed fusion: original shell (A) as well as shell (B) redesigned to avoid overhangs using one of two possible solutions, (1) and (2).

No supports means no scrap. It means no wasted material, no unnecessary build time and not nearly as much post-processing. It also means simpler geometries are easier to make, as are more complex geometries. Take a pressure vessel, for example. They are relatively simple in terms of shape, but could not be easily replicated with L-PBF processes that require supports, because a portion of the internal shell structure is likely to exceed the critical overhang limit (see Figure 2). Redesigning the internal structure of a pressure vessel in order to eliminate overhangs that need supports requires extra engineering effort, time and cost, and it drives up risk — and good luck passing code. Code cases for AM pressure vessels are still in development.

So while eliminating supports may sounds like a small thing, it is big for metal AM. It means that process substitution is exactly that — process substitution, not redesign to make AM work. Thus, companies can spend their time and money qualifying an AM process and the associated material feedstocks, not re-engineering parts, and the uphill battle is no longer as steep.

Related Content

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read More