People, Process and Principle: How to Thrive in Adversity

Trinity Precision has found success by sticking to its principles, refining processes and putting people first, even in times of adversity.

Share

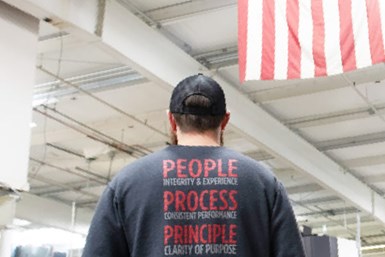

On the shop floor, a Trinity Precision employee proudly sports a tshirt with the shop’s motto.

Visitors to ’s facility are greeted with “People, Process and Principle” on the wall as they enter our building, and for good reason. These three focuses have served us well in both good times and bad. Over the past 18 months, we have worked to continue putting our people first, improving our processes and standing on a firm foundation of principle to guide us. While businesses like ours need to make a profit, there are times when we need to remember the tremendous impact, as employers, that we have on our team. We can’t change everything going on in the world, but we can have an enormous impact on the people we work with and their families. Imagine how many people they impact as well.

When a downturn or disaster happens, it is important for us to stand unshakably on our principles. In the midst of the recent downturn in the aerospace market, we continued to practice our people-first principle. After many companies had already had two or three rounds of lay-offs, we were still able to hold onto our team. Instead of cutting positions right away, we found other ways to reduce costs and rally our company.

Through our “Catch up, Clean up, Rise up” campaign, we refocused our attention in the downturn. During adversity, we found our strength in doing the things we had a difficult time accomplishing when business was booming. Over the past five years, our business has quadrupled. We used the downturn as a time for our team to review our processes and address issues we had in our previous five years while simultaneously preparing for future growth in the next five years. “Prepare for bad times in good and good times in bad,” as my father would always say.

We found that, while we did not have the same frantic pace from work we received during our growth prior to the downturn, we did find a new focus for improving our processes and positioning ourselves to be ready for the next wave of growth. Part of that focus was to ensure that we did things to show the team our commitment to them and their future. These included starting a ramp-up period for matching our 401(k), absorbing all our healthcare cost increases into the company, adding key positions in areas that allow us to onboard new parts faster and focusing on a robotic cell that runs high-mix and low-volume production work.

In addition, we hold a weekly “all hands” meeting for everyone in the company to communicate what is happening within the business. Nature will fill a vacuum, and our imaginations will fill in for facts when people are not told what is happening inside a company. Rarely is the positive imagined. This weekly communication allows us to help our team understand and focus on the realities we are facing. It also discourages the creation of mythical problems that could divert our team’s energy onto the wrong issues to address. At these meetings, we also get insights into our teams’ concerns, and make sure to address them to the best of our ability.

In times of difficulty, we believe there are a couple of key things to put in front of the bottom line that will impact the bottom line in a positive way. Be firmly planted on your principles. Keep your focus on your team so they can keep their focus on the company. The more transparently and frequently managers communicate with their teams, the better the teams can focus on the real issues the company faces.

Prioritizing people, process and principles ensures that, even in adversity, teams will grow stronger and better.

Related Content

4 Rules for Running a Successful Machine Shop

Take time to optimize your shop’s structure to effectively meet demand while causing the least amount of stress in the shop.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreRead Next

Last Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More