Share

Universal Robots (UR) recently released a new cobot called UR20 — a cobot with a lift capacity of 20kg, a 25% increase over anything the company has offered. As the use of cobots gains traction in job shops — specifically for machine tending, moving materials, and assisting with secondary operations — UR envisions the new model to work for a wider range of scenarios that previous models couldn’t handle. I spoke with Anders Beck, vice president of innovation at UR’s headquarters in Denmark, about the development of the UR20, technical hurdles the team had to overcome, and how the new model will impact the market.

Anders Beck, vice president of innovation at Universal Robots. Photo Credit: Universal Robots

MMS: What is the significance of offering a 20kg cobot and how will it impact your customers?

AB: We're very proud to launch a 20 kg cobot with 1,750mm of reach. To create a robot that delivers performance and reliability while fitting into human-scale tasks in the work environment has been important for us to get right. We had to redesign a lot of parts because our mechanical design has been around for quite a while, and the demands that this cobot put on the drive train we had been using created new challenges. We really wanted to make sure that we ironed out all of the functionality and make a mechanically superior product compared to where we came from.

In upgrading the drive train, we wanted to bring both a boost in uptime and reliability but also give a product that is really capable of sustaining a heavy load.

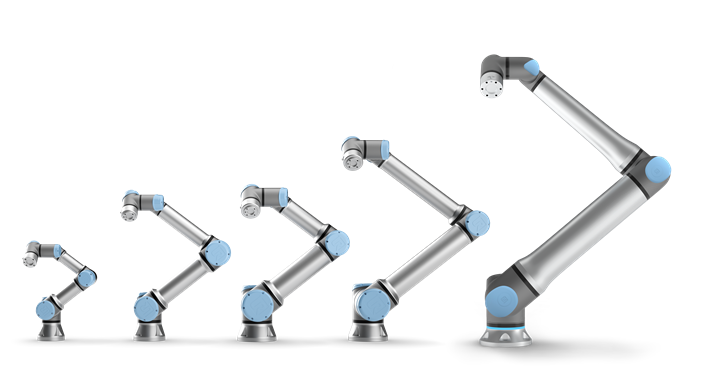

The UR20 has twice the reach and 25% more payload capacity than the previous generation of cobots from Universal Robots.

Photo Credit: Universal Robots

MMS: What was the need that Universal Robots identified here? What were the projected applications that drove the project?

Palletizing is a common way to demonstrate the abilities of a cobot. In machine shops, cobots fill many roles, from machine tending to part picking to quality inspection. Photo Credit: Universal Robots

AB: I think there's a lot of tasks out there that need this kind of work. Of course, there's packaging, palletizing and other situations where people carry boxes and stack them up high. It is common to see people in this industry moving 10 tons of material a day. Over a lifetime, that's not what we want for our workers. A lightweight robot capable of carrying that kind of weight will change people’s lives.

Having that work done by cobots enables people to stop doing that kind of work, but we’ll also see this cobot in other places like welding and machine tending. These cobots will support machine tools like lathes and CNCs because of the ability to reach further into machines and situations where heavy parts are now within its capacity. And because the whole installation has become a thing that is possible for most professionals, you don't need a lot of different stakeholders to be involved with the programming.

MMS: What kind of engineering upgrades made the UR20 possible?

We had to re-imagine the whole drive train. If you look at the base joint of the UR20, it produces a bit more than 700 Newton meters of force, so the torque it produces is huge but the repeatability at the end of the arm is still 50 microns. We had to work closely with our key vendors and we really thought through the whole mechanical design and simplified the process. We put our attention toward critical aspects of the cobot, especially with the rigidity of the system.

See the UR20 in action in this video by Universal Robots:

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreTranslating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreRead Next

Machine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read More