Quickly Give Live Tools Coolant-Through Capability

This retrofit system enables users to quickly and easily add through-tool coolant delivery on their live tooling.

Share

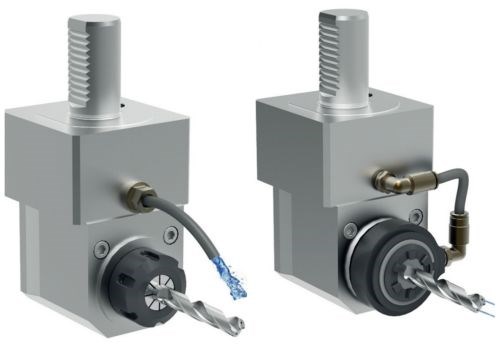

The Recool system from Rego-Fix enables users to quickly replace the conventional spray-pipe coolant delivery system on their live tooling (left) to through-tool coolant delivery (right).

Through-tool coolant delivery is more effective at getting coolant to a tool’s cutting edge than spray pipes or nozzles. Knowing this, Rego-Fix has developed a retrofit through-tool coolant delivery system for live tooling on CNC lathes that is said to install in minutes.

The animation demonstrates how simple it is to install this affordable system. Each Recool kit contains a special clamping nut with outer ring, a coolant pipe and a few fittings. The standard kit achieves maximum speed and pressure of 6,000 rpm and 300 psi, respectively, although higher speeds and coolant pressures are available upon request.

Related Content

-

Henkel Redefines Industrial Machining and Grinding with Sustainable Metalworking Innovation

With innovative formulation and bio-resistant properties, Henkel’s new semi-synthetic lubricant emerges as a pioneering solution in the machining industry.

-

Sustainability Project Cuts Costs for Growing Manufacturer

A custom coolant and chip management system has helped Youngers and Sons lower its supply costs, improve its recycling margins and maintain a clean shop floor.

-

Considerations for Machining Coolant Care

Coolant care can be simply managed if you know where to pay attention and which hazards to look out for.