Reaming Application Illustrates True Cost of Cutting Tools

Cutting tools have two costs: purchase price and combined cost of all time, effort and extra steps required for a particular tool.

Share

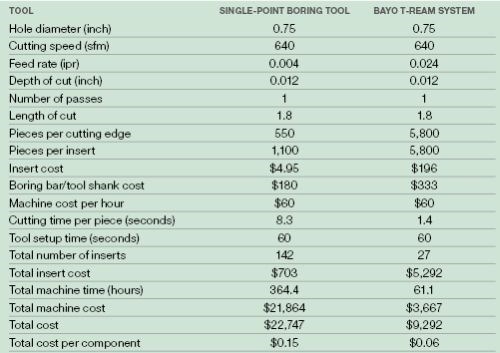

One caveat is that this search for savings often requires a change of thinking. Previously, the injector body manufacturer saw the critical hole as a boring application. The savings came when the company saw it as a reaming application instead. Something similar frequently occurs in milling work, Mr. Edler says. Many facilities can double their metal-removal rate in milling, but doing so requires the counterintuitive step of switching to a high-feed milling tool design that mandates a light depth of cut—lighter than what the shop is taking now. Running this tool at a substantially higher feed rate can more than overcome the lighter cut to save overall cost. In applications such as these, he says, the cost-effective approach often looks very different from the way that a given part or feature has historically been machined.

Related Content

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

Read MoreHeule Cutting Tool Provides Chatter-Free Countersinks

PMTS 2025: GH-K tooling is well suited for conventional milling of chamfers around the perimeter of larger holes or entire parts.

Read MoreMeasuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreRead Next

Last Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreAMRs Are Moving Into Manufacturing: Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More