Share

This content originally appeared on our sister brand, Additive Manufacturing Media. Get articles, podcasts and loads more AM content at .

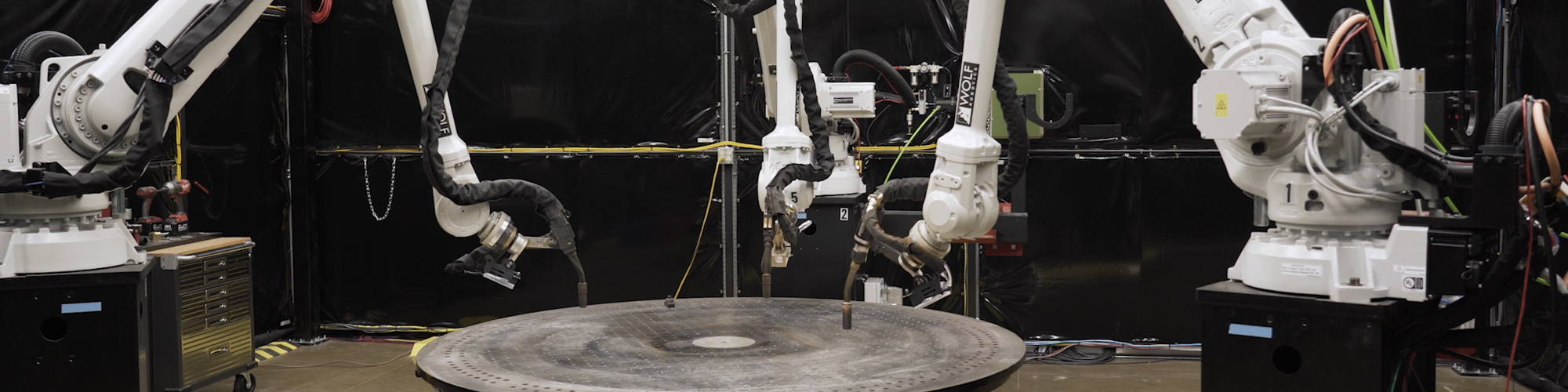

When robots perform deposition-style 3D printing, adding more robots offers the chance to build large parts faster. The Medusa system developed at Oak Ridge National Laboratory’s Manufacturing Demonstration Facility combines three robots performing directed energy deposition (DED) metal additive manufacturing via Lincoln Electric Additive Solutions’ wire arc additive manufacturing process. The robots apply material in synchronized motion around a shared indexing turntable, and future versions of the system will add even more robots.

Related resources:

- Oak Ridge National Laboratory

- The way ahead for

- Why additive manufacturing and robots

- Another example of

Related Content

-

3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.