Shoe Manufacturer Improves Time To Market With CAM Software

Speed is one of the selling points athletic shoe manufacturers use to market their products: Buy their shoes and you'll run faster. But speed is not just a factor in selling shoes; it has become an essential in their manufacture as well.

Share

Speed is one of the selling points athletic shoe manufacturers use to market their products: Buy their shoes and you'll run faster. But speed is not just a factor in selling shoes; it has become an essential in their manufacture as well.

At the Adidas Footwear Design Center in Portland, Oregon, designers develop prototype shoe soles with various shapes and tread patterns. The prototype begins with a 2D version, which is often a simple sketch. The sketch is given to the design center's CAD department, where a 3D model is developed. The 3D model may be divided into as many as six parts. Each part is individually machined from Ren Shape, a synthetic wood material, on a four-axis mill. The Ren Shape parts are then vacuum cast to create flexible parts. The flexible parts are assembled to form a single model that is put through a series of durability tests.

Once a model passes these tests, it is returned to the designer for approval. If it is approved, then the data from the prototype are sent to a contracted, independent mold shop where a 3D model is cut and a mold is cast from silicone. The finalized sole is then molded and incorporated into the manufacturing process of the shoe.

Adidas' moldmaking and manufacturing operations are performed in Asia. In the past, because the design center did not have a CNC machine, 2D blueprints were sent to Asia and turned into sample 3D models, which had to be approved by the designer in Portland. This process frequently required designers to take expensive flights from Portland to Asia. Because the models often underwent revisions, valuable materials and labor hours were wasted.

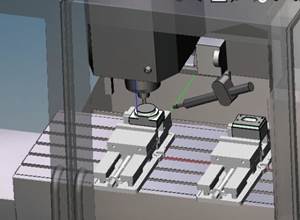

To cut costs, Adidas placed a CNC machine at the design center and looked into purchasing CAM software. After researching several companies, Adidas decided to purchase Open Mind Software Technologies' (Southfield, Michigan) hyperMill CAM software. According to Lafe Christopherson, CNC/CAM specialist at Adidas, production time for a detailed prototype model, from design to designer-approved model, has been reduced by about half since the shop began using the software in March 2000. The 3D models are now machined in Portland, reducing the need for trans-Pacific flights and ensuring the formation of accurate molds.

Doing more work in-house also means a shorter time to market and the manufacturing and distribution of more shoes. It also allows Adidas to stay aware of trends in the competitive world of athletic shoes and to react more quickly to those trends.

Adidas takes advantage of several of hyperMill's automated NC programming functions. Z-level roughing and re-roughing are used to remove the largest amount of material in the shortest time. By using an in-process model, the software can keep track of the material left by the previous cutter and only re-machine those areas. Another feature is slope machining, which detects surface angles and applies the appropriate type of machining method based on those angles. This provides the best surface finish possible.

Open Mind has also provided Adidas with a tool that minimizes programming time. Once parameters and other settings are entered into the program, hyperMill's nightShift utility can calculate tool paths for multiple parts without supervision. Mr. Christopherson says this task can take up to three hours, and before nightShift, he would sometimes program tool paths until 3 a.m.

"I can load the part information and go home," Mr. Christopherson says. "The tool paths will be calculated by the beginning of the next day."

Overall ease of use is the quality of hyperMill that Adidas found most attractive. According to Mr. Christopherson, the software makes it easy to set up parts and to create tool paths for machining complicated surfaces. It also integrates with Adidas' CAD program, think3, and it allows users to convert CAD programs directly into NC programs for processing without leaving the CAD desktop.

Reduced training time is another benefit, Mr. Christopherson says. It took just a short time for him to be able to produce an error-free model. And Mr. Christopherson is able to train other employees—some of whom have had no previous CAM experience—to use the software in just one week. "It's just not that hard to pick up," he says.

And, of course, there is speed. The software allows frames to be set and parts to be rotated more quickly, Mr. Christopherson says. He adds that hyperMILL runs extremely fast when working with multi-axis machines.

Adidas has a goal of cutting its prototype-to-market timeline from its current 18 months to 9 months within the next two years. Mr. Christopherson believes that with the help of hyperMill, that goal of increased speed will be easily attained.

Related Content

Turning the Corner on Virtual Machining and Simulation

Simulation software’s effectiveness comes down to proper implementation and alignment with shop priorities.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreRead Next

Last Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More