The Lowdown on Machine Tool Lubricants

Need help choosing the right lubricant for your machine tools and workplace environment? Here’s a resource to help keep your equipment humming along.

Share

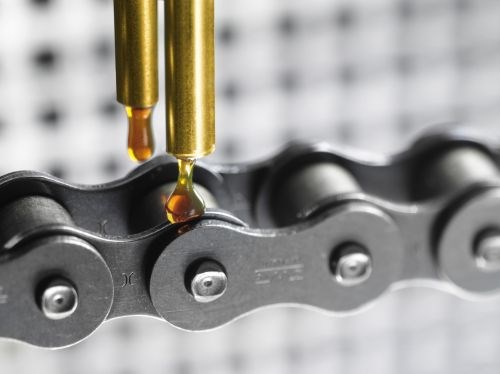

Proper lubrication management is central to the long service life of your machine tools. Choosing the right mix for the type of work you’re doing, as well as the environment you’re doing it in, will pay off in the long run. To aid in selection, Klüber Lubrication has developed a that provides insights for a variety of markets into how the proper lubricant solutions save energy, protect equipment and enhance processes. The kind of information you’ll find includes:

- Product spotlights that describe lubricant properties and areas of likely applications such as couplings, joints and gears.

- Blog overviews from a Klüber expert about special application issues like the advantages of using synthetic ester oils, high viscosity index (VI) base oils or high-performance NSF H1 food-grade lubricants.

- White papers that provide in-depth information about test procedures, lubricant properties and application techniques.

- Case histories that detail successful application in various industries, climates and hazardous environments.

- News releases on the latest developments in lubricant solutions for new applications, government regulations and other timely issues.

Related Content

-

Master Fluid Solutions Semisynthetic Coolant Inhibits Corrosion

Trim MicroSol 685XT is designed to provide enhanced corrosion inhibition on all ferrous and nonferrous metals.

-

LNS Chipblaster Provides High-Pressure Coolant Using CNC Interface

The Chipblaster S Series is designed to precisely apply high-pressure coolant where and when required.

-

Sustainability Project Cuts Costs for Growing Manufacturer

A custom coolant and chip management system has helped Youngers and Sons lower its supply costs, improve its recycling margins and maintain a clean shop floor.