Where More Flutes Make Sense

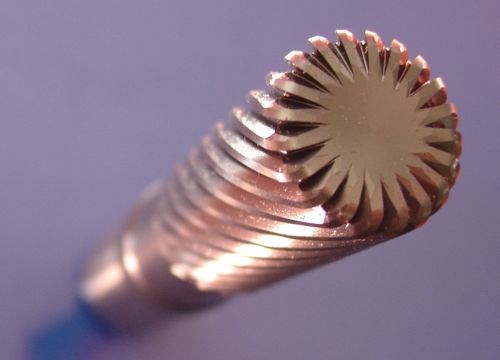

A tool with many flutes can be effective for achieving a productive metal removal rate in titanium, where speed and chip load are constrained.

Share

MAG’s cryogenic machining is an extreme response to the danger of heat in machining titanium, but the company says heat has always been the enemy. The company offers 20-flute end mills for titanium because the large number of flutes offers a way to cut at low surface speed and light depth of cut, but still maintain a high metal removal rate through a high inch-per-minute feed rate. See video of a 20-flute tool.

Related Content

-

Stability Maps for Milling

Selecting stable radial depths of cut for 2.5D milling.

-

Tungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

-

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.