Doosan's Multi-Level RPS for its NHP Series Cuts Setup Time

Doosan Machine Tools has introduced a multi-level RPS for the NHP Series of horizontal machining centers, which cuts setup time and adds capacity.

Share

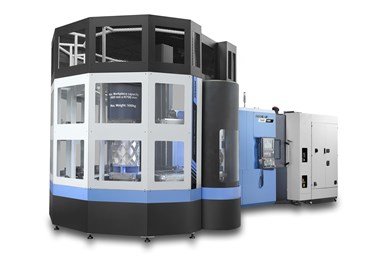

Doosan Machine Tools’ multi-level Rotary Pallet System (RPS) for its NHP Series of horizontal machining centers fits into the company’s product line between the high-end Linear Pallet System (LPS) and the single-level RPS, which is cost-effective, but not expandable if growth demands it.

The multi-level RPS holds up to 21 pallets (three layers of seven pallets) vertically, saving floor space. Doosan believes the new configuration will be attractive to job shops needing to add capacity to their machine or requiring an affordable, compact pallet system to consolidate fixtures that may be feeding their horizontal machining centers. With JIT scheduling, the RPS can help job shops catering to multiple industries (where tasks may change from month to month) cut down on setup time.

The RPS is equipped with a user-friendly HMI screen that communicates with the CNC operating the horizontal machining center. The main CNC also stores programs and tool data.

Doosan says the high-throughput NHP machines’ thermal stability, vibration dampening strength, high acceleration and deceleration and quick chip evacuation pairs well with the multi-level RPS.

The center trough chip evacuation on the NHP series allows chips to fall directly underneath the spindle, letting gravity do the work. Although accumulation of chips inside the machine’s work envelope can cause many mechanical failures and alarms and negate the value of the RPS, maximum ceiling shower coolant and bed flush coolant allow chips to gather in the trough and then into the lift-up chip conveyor for proper disposal.

The company also points out the benefits of the modular approach used in the NHP series, which allows expansion of the tool magazine from the standard 60 to a 275-tool matrix. This expansion means an operator can load enough tools to machine all the pallets stored on the RPS.

Related Content

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.