DP Technology Optimizes ESPRIT for Willemin-Macodel

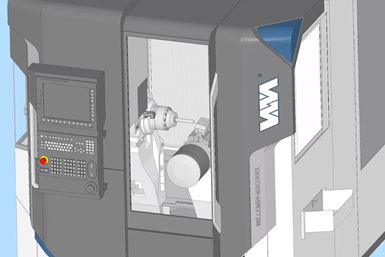

DP Technology has worked with Willemin-Macodel to optimize the ESPRIT CAM software for Willemin-Macodel’s complex mill-turn machines.

Share

Although the complexity and strict precision requirements for workpieces manufactured on Willemin-Macodel’s mill-turn machines made using traditional CAM software challenging, DP Technology worked directly with Willemin-Macodel to improve programming efficiency and user experience for Willemin-Macodel’s MT machines in DP Technology’s ESPRIT CAM software.

Benefits of this work include a simplified user interface for setting global machine settings, as well as capabilities for outputting machine-optimized, edit-free G-Code; creating and sorting operations in the required work coordinates; optimizing simulations to match the output NC code and actual machine behavior; displaying operation information to ease programming in ESPRIT; swift mounting of vise jaws on the turret and chucks and collets on the main and sub spindles; programming of tailstock and vise steady rest engage and disengage cycles; and flagging milling operations as cutoff operations.

DP engineers also worked closely with Willemin machine specialists to create a turn-key digital machine package consisting of post processors and virtual machines for the MT series. This package eliminates the time spent on editing the G-code and streamlines the machine setup and first article run off for end users.

DP Technology says ESPRIT provides not only a dedicated CAM solution for Willemin-Macodel machines, but also extensive engineering expertise and knowledge to make sure end users can start quickly and keep running at top efficiency using the MT series machines.

Related Content

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.