High QA's Inspection Manager 5.0 Improves Support for ISO, BSI, ASME Standards

High QA’s Inspection Manager (IM) 5.0 includes features for higher quality standards and increased automation.

Share

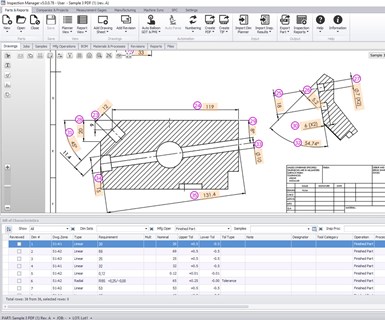

High QA’s Inspection Manager (IM) 5.0 includes features for higher quality standards and increased automation. Designed and built as a database-driven software, IM 5.0 is an integrated set of applications, including quality management modules like One-Click geometric dimensioning and tolerancing (GD&T) extraction and automatic ballooning using advanced AI-driven OCR; inspection planning; data collection and organization; automated import of inspection results from coordinate measuring machines (CMMs), vision measuring machines (VMMs) and other connected measurement equipment; in-process shopfloor inspection results collection; creation of standard and custom forms and reports; Integrated SPC tracking and reporting; user-access security management control; ERP integration; and more.

IM creates inspection plans, balloons PDFs, consolidates results and generates reports to AS9102, Medical Industry Standards, AIAG/PPAP, and other standard or custom forms. Version 5.0 features enhanced support for metric dimensions, ISO, BSI and ASME metrology standards.

One-Click OCR GD&T extraction and ballooning from 2D drawings, PDFs, TIFF, or other image files is a fundamental component of IM. In version 5.0, that feature now includes support for surface finish and welding symbols, saving time in the initial phase of inspection planning. The software now streamlines the various modules and systems integration and maximizes automation and efficiencies to meet current and future measurement and inspection quality demands and requirements.

Enhanced job lifecycle management provides greater workflow support, managing jobs and batch records as they move from stage to stage in the process. A database upgrade addresses various installation scenarios, including external MS SQL server locations and advanced database administrator (DBA) settings.

Related Content

-

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

The Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.