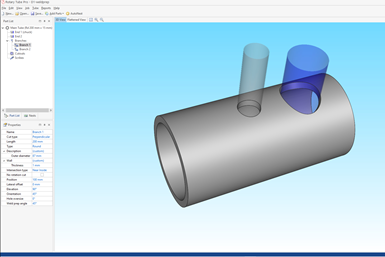

Hypertherm Rotary Tube Pro 3 Simplifies Tube Part Cutting

Hypertherm’s Rotary Tube Pro 3 includes updated features like common line cutting and comprehensive costing to simplify the user experience of designing and cutting tube parts.

Share

Hypertherm has released Rotary Tube Pro 3, a major version update of its tube and pipe cutting software for machines with a rotary axis. This new release contains new features and enhancements the company says simplifies the process of designing and cutting tube parts.

Common line cutting allows operators to cut two or more parts so that they share at least one common line with one another, providing greater material utilization and better consumable life. Updated costing for parts, nests and jobs includes factors such as consumable wear, machine operating cost, labor costs and electricity. Auto-selection of material enables operators to enter basic material descriptions in settings and automatically map to available materials — meaning they no longer need to separately pick a material and thickness after selecting a tube size and wall thickness.

“With Rotary Tube Pro 3 we’ve responded to our customer base with features and enhancements that we believe take a big step forward,” says Steve Bertken, product manager for Hypertherm CAD/CAM software products. “With common line cutting, users now have the ability to completely eliminate scrap between parts, potentially reducing their material costs and achieving better overall efficiency.”

Hypertherm says customers with an active maintenance plan can upgrade to the new version at no additional charge and continue to receive unlimited technical support and other benefits.

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.