Kyocera SGS End Mills Feature Seven-Flute Design

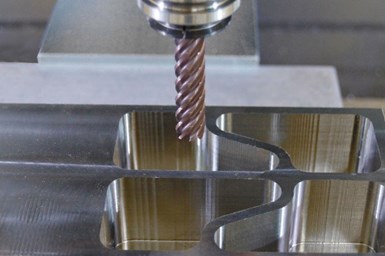

The H-Carb Series 77 end mills feature a specialized core and flute design to improve rigidity and chip flow while reducing deflection.

Share

Kyocera SGS Precision Tools has expanded its H-Carb seven-flute, high-efficiency end mill series with an array of larger corner radii options.

The H-Carb Series 77 end mills specialize in deep axial trochoidal and high-speed machining applications and are offered in various lengths of cut. The specialized core and flute design improve rigidity and chip flow while reducing deflection. The seven-flute design is designed to enable superior finishes at higher speed and feed rates versus five- and six-flute tools.

The H-Carb portfolio now includes 72 new tools featuring 2-, 3- and 4-mm corner radius sizes and are available in three lengths of cut (2.5×D, 3×D and 4×D). Coatings are available in Ti-namite-A and Ti-namite-M, making them suitable for dry machining in ferrous-based materials such as cast irons and numerous carbon steels. The chipbreaker profile is standard with a wide range of square end and corner radii options offered to meet a variety of machining specifications.

Benefits of the portfolio include a heavy-duty core and specialized flute design for improved rigidity, chip flow and reduced deflection; a chipbreaker profile that aids in chip flow, especially in deep pocketing operations; deep pocketing and slotting capability using the various lengths of cut offered applying a trochoidal tool path; and CAM programming methods using high-efficiency machining by applying trochoidal tool paths and incorporating constant cutter engagement.

Related Content

-

Five Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.