Mitutoyo AI Inspect Uses AI-Enhanced Visual Defect Analysis

Mitutoyo’s AI Inspect program enables operators to leverage AI-enhanced modules for visual defect analysis.

Share

Mitutoyo America Corporation has added AI Inspect to its software lineup. Mitutoyo AI Inspect is a standalone software product designed to assist customers with next-generation visual defect analysis across multiple applications.

The software’s headlining features are the distinct Training Module and Runtime Module. The first of these enables users to develop inspection routines for automated implementation of defect detection using image sets, while the Runtime Module incorporates these inspection routines into the system.

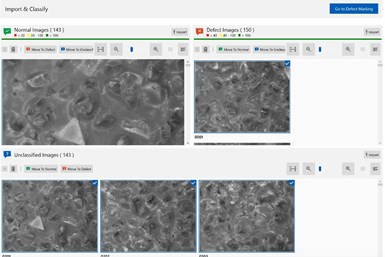

The Training Module’s methodologies include importation, organization and storage of user-defined inspection projects; integrated tool sets and techniques for loading and classifying normal and defect image sets; an interface that enables the operator to mark and highlight defects on images; a section that enables operators to account for brightness, noise and focus differences; an interface that updates the operator on the progress and success of the training sequence; and an interface that allows operators to review image, pixel and component predictions. Users deploy models with unique identifiers for added clarity.

Mitutoyo AI Inspect’s Runtime Module includes an inference testing application for reviewing the AI model with sample testing on new images.

Related Content

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

-

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

-

Leveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.