Open Mind Technologies CAD/CAM Software Suite Enhances Intelligent Workflow

IMTS 2024: Open Mind Technologies showcases its hyperMill CAD/CAM software with enhancements to its toolpath capabilities, overall functionality and more.

Share

Open Mind Technologies is highlighting the HyperMill 2024 CAD/CAM software suite. The company recently introduced its latest HyperMill 2024 CAD/CAM software suite version which includes a range of enhancements to its core toolpath capabilities, as well as custom functionality for increased NC programming efficiency in applications ranging from 2.5D machining to five-axis milling.

The software suite’s optimized deep-hole drilling CAM strategy is said to offer improved machining reliability by providing a user-friendly interface with process-relevant parameters clearly defined on a process tab. According to the company, these capabilities enable coolant and dwell time stages to be identified, permit a chipbreaker to be integrated into a drilling process and more. A custom single-tip gundrill tool simulation function can provide precise collision checking and a detailed visualization of the stock removal.

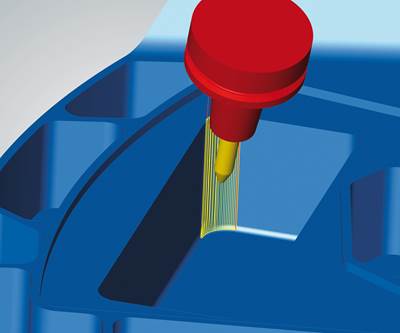

An algorithm for three-axis and five-axis rest machining is also highlighted. It is said to ensure automatic, complete detection of all rest material areas, in addition to optimized toolpath calculations for faster, reliable machining. Tool paths are optimally divided to enable more efficient machining, and the detection of intersection areas where paths meet is optimized for collision avoidance.

An additional Open Mind toolpath variation is a path layout for the 3D Plane Machining cycle. This strategy is designed for a smoother path and fewer pick-ups. While the toolpath length (distance) may be longer in some cases, the machining time, as tested on a variety of NC controllers, has been reduced.

The “CAM Plan” is included in the HyperMill 2024, designed to simplify various programming tasks and identify possible sources of error. Pre-defined workflow steps guide users through the preparation and programming process, while the geometries and features required are automatically created. Also, potential errors are flagged for removal such as double surfaces or gaps between model patches.

Once the data is organized, the CAM workflow can be processed with more intelligence and efficiency. According to the company, the first benefit from HyperMill CAM Plan is that component topology is analyzed to produce a precise tool path that has command locations aligned with key geometric features and with optimized point distribution for milling. The results improve surface finishes, simplify processing by NC controllers and reduce machining times.

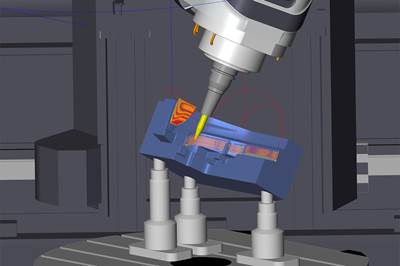

The company is also highlighting an additive manufacturing capability option in the HyperMill software suite to support 3D printing/additive and hybrid processes. It is said to provide efficient hybrid processing with simultaneous additive and subtractive processing on one machine. It can enable an array of flexible options for directed energy deposition processes (DED) and wire arc additive manufacturing (WAAM) for complex five-axis simultaneous processing. Both laser-based powder nozzle machining heads and WAAM can be controlled using HyperMill additive manufacturing for selective material deposition, as well as programmed and automatically simulated for collision avoidance.

Using powder bed fusion (PBF) and any necessary rework, HyperMill can enable users to program cladding and milling together. True-to-detail additive and subtractive simulation, as well as stock tracking between the individual process steps, are intended for optimal reliability. Key additive applications include repair of damaged components, cladding of additional surface skins or creation of new components from a substrate. This can also create custom options for combining different materials, such as when high-quality material layers need to be applied to carrier materials.

A virtual machining capability for additive manufacturing processes is also offered, where machines often have limited axis ranges. The HyperMill Virtual machining optimizer can be used during NC code generation to simulate additive tool paths to optimize them for the machining.

For simpler generation of three-axis and five-axis NC programs with axis change and an optimized use of the workspace, the NC Optimizer feature in the HyperMill V Machining strategy offers the option to transform X- and Y-axis movements into a movement that utilizes the rotation axis in the table. By swapping axes, an XY movement is transformed into a simultaneous CX movement, which eliminates rewind movements during machining. This can be especially impactful on machines that have a limited linear axis range.

The reading back of measuring points when using HyperMill Virtual Machining is a feature that enables graphical representation of measured points on the part model, rather than comparing a list of measurement results. Users can also quickly identify measuring points that are out of tolerance on a 3D part model and compare trends over sequential measurements. As a result, it is much easier to analyze and compensate for inaccuracies and tool wear after milling.

Related Content

SMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

Read MoreEmuge-Franken Skiving Tools Improve Precision for Tool Grinding Machines

Emuge-Franken USA is showcasing its line of clamping and skiving tool solutions, designed to improve precision and accuracy in tool grinding machines.

Read MoreAI, Data and the Digital Manufacturing Future

AI has the potential to reshape manufacturing software — but first, it will require data.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreRead Next

Open Mind Introduces Updated HyperMill CAD/CAM Software

Eastec 2021: Open Minds’s CAD/CAM software suite update reportedly offers enhancements for applications ranging from 2.5D to five-axis.

Read MoreOpen Mind Technologies' HyperMill CAM Software Enables Real-Time Synchronization and Simulation

EMO 2019: Open Mind Technologies’ HyperMill CAM software was developed with Industry 4.0 in mind.

Read MoreAMRs Are Moving Into Manufacturing: Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More