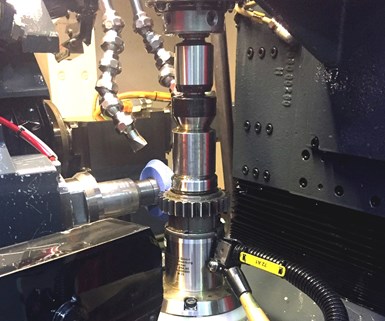

Ringspann's HDDS Mechanical Clamping Mandrel Increases Process Security

Ringspann’s HDDS expanding-sleeve mandrel is designed for clamping spur or taper wheels for gear manufacturing.

Share

Ringspann’s HDDS expanding-sleeve mandrel is designed for clamping spur or taper wheels for gear manufacturing. The HDDS, an inner clamping system, is marketed as a mechanical alternative to hydraulic expanding mandrels commonly used in gearmaking. It provides true running accuracy of equal to or less than 5 microns and achieves absolute expansion some four times larger than many other hydraulic clamping fixtures, the company says.

“Our HDDS can take up workpieces with bores of up to tolerance class IT10,” says Production Manager Joe Thompson. “Most hydraulic clamping fixtures, meanwhile, are only suited to take up workpiece bores up to tolerance class IT7.”

Because mechanical fixtures do not leak, they provide more process safety in series production than hydraulic fixtures, the company says, adding that even the smallest leaks can lead to process interruptions, malfunctions and increased repair outlay. The only source of wear for Ringspann’s HDDS is its clamping disks. Furthermore, the clamping mandrel doesn’t need to be taken from the spindle to replace these disks.

Related Content

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.