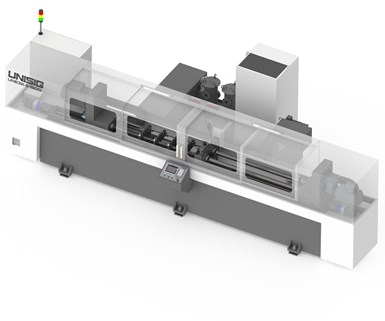

Unisig's UNE Gundrilling Machines Provide Flexibility for Job Shops

Unisig’s next generation of UNE gundrilling machines is said to provide operational flexibility, improved performance and easier operation.

Share

Designed for manufacturers in high-volume/low-mix or low-volume/high-mix production environments, Unisig’s next generation of UNE gundrilling machines is available in five models built from two frame sizes. UNE machines can drill hole diameters ranging from 1.4 to 40 mm with depths up to 3,000 mm. Compact construction is an advantage for positioning and relocating the machine on crowded shop floors. The machines also can be equipped with robotic automation.

The single main spindle servo motor delivers the necessary horsepower for the two-spindle machines. When power is applied in single-spindle mode, however, shops can produce larger-diameter holes to increase their capabilities and add new business without adding a new machine, Unisig says.

Rather than a pressure-based coolant system, the UNE series features a programmable flow-based coolant delivery system to provide the right amount of fluid to the tool’s cutting edge.

An automated door option can benefit companies with or without automation by reducing fatigue and improving throughput.

Related Content

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

-

Addressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?