Automation

Sourcing Automation

A new kind of 'automation project manager' helped this company install a roboticized machining cell, the first of several now operating in its plant.

Read MoreAutomation's Extended Reach

The experience of a Windsor mold shop offers an object lesson in machine shop automation. In an interconnected process, automating one aspect of the process offered benefits beyond what the initial planning had led the shop to expect.

Read MoreGetting To Know Knowledge-Based Machining

The term refers to different levels of automation that CAM software developers are building into their NC programming software.

Read MoreAutomating The Mold Shop

This shop produces dies and molds around the clock 7 days a week, yet most of the time no one is there.

Read MoreGet Fat—In A Good Way

A shop's next big improvement in efficiency or capabilities may require the kind of understanding that can only come from personal investigation, or from experimentation. New automation, for example, may require new operator procedures to be proven out.

Read MoreHarnessing The Quality Engine

Honeywell鈥檚 Phoenix aerospace plant uses a dedicated CMM to ensure quality and reduce costs in a high-volume manufacturing cell.

Read MoreOn The Path To Automation

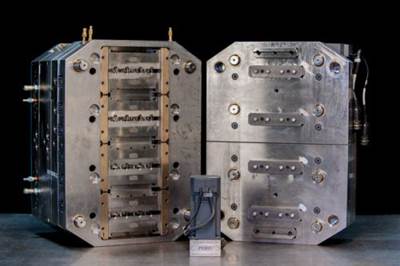

Implementing an integrated tooling system proved to be this mold shop's first step toward automated operation of its electrical discharge machines and graphite mills. Today, the shop's robotic cells can run around the clock in an unattended mode.

Read MoreCompeting With Automation

Who would have guessed that an electrical discharge machine could work so fast that it would need a robot to keep it busy when everybody had gone home for the day? Who would have guessed that mold making, the epitome of skilled craftsmanship in metalworking, could lend itself to some of the most advanced automation in manufacturing? Who would have guessed that molds could be designed with so many cavities and inserts that all the electrodes and components needed to produce such molds would multiply and multiply and multiply? Who would have guessed that completing a complex, high quality mold in one half or one third of the normal time could be the new standard for mold work around the world? Who would have guessed that workers in mold shops overseas could be so talented, well trained and well equipped yet paid so little? Quite a few mold shop owners and managers in our part of the world did guess right about these things. They figured out what was happening years ago.

Read MoreAutomatic Pallet Systems Increase Production And Quality

These pallet changer systems not only improved this tooling manufacturer's labor situation, but they managed to increase their production as much as 600 percent on some of its indexable cutting tool products.

Read MoreMulti-Station Repeatability Enhances Quality For Complex Parts

Flexible automation is making production machining a new opportunity for shops that traditionally did not seek this kind of work. At the same time, automated machining systems are taking new shapes and configurations that favor this trend. A recently introduced example is the Turn 6 LC from ATS.

Read More