Are Increasing Oil Prices Good for U.S. Industry?

The positive impact of oil prices on modern U.S. manufacturing offers an argument for questioning our habitual response to oil price increases.

Share

Which is better for the United States: high oil prices or low ones? For now, the answer is still the latter—but the answer might change as U.S. energy imports and exports increasingly . OPEC recently announced that it would stop supporting the low oil prices we have been seeing by . Should we be cheering this news or booing it?

My reflex is certainly to boo it. I grew up being taught that this is the response to expensive oil. My parents remember oil shocks and lines at gas stations, and throughout my own decades as a driver, I’ve seen the price to fill a car’s tank sometimes represent an alarming expense.

And yet, advances in oil and gas extraction in more recent times have helped to make the United States a more significant energy exporter. One result of this is something I’ve seen clearly from my vantage with MMS: a notable amount of domestic manufacturing activity hinges on oil prices being high. Indeed, I’ve heard repeatedly about the struggles shops making oilfield-related hardware have faced in recent years when prices have been low. Some have sought ways to serve the industry differently, some have sought to attract business from different industries, and some have closed altogether. In this sector, higher oil prices would have a welcome, positive effect.

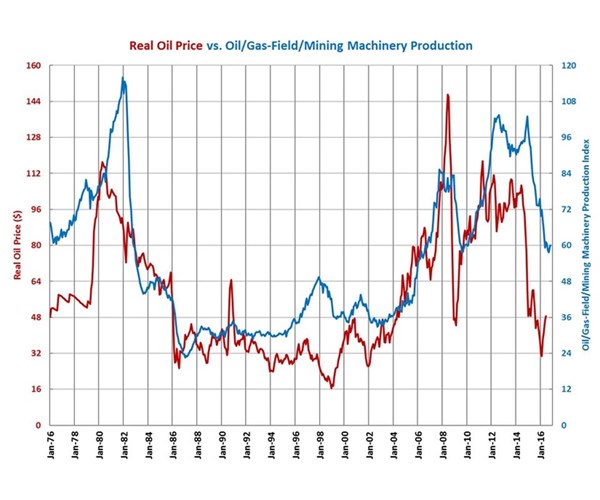

Here is a picture of that effect. This graph, which is based on Federal Reserve data, was created by Gardner Research (source of all the graphs in this post) to show the inflation-adjusted price of oil versus production activity for manufacturers of oil and gas equipment. Statistically, the correlation is about 80 percent, a connection that can be seen here without much difficulty. On this graph, when the oil price rises or falls, the business activity for oilfield equipment producers does the same thing not long after.

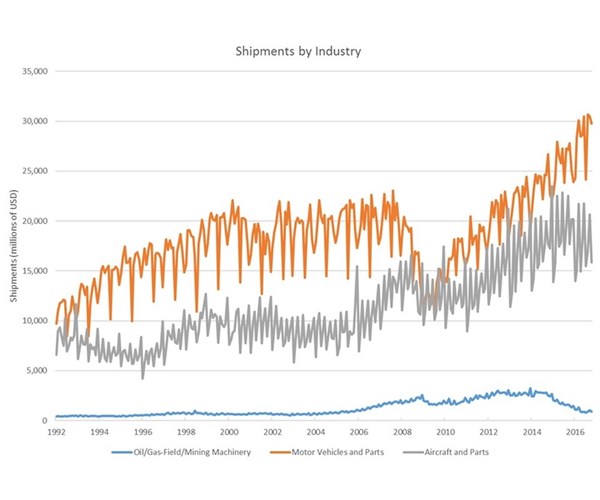

But what is the effect of this more broadly? How much do higher oil prices help (if they even do help) manufacturing overall? This graph offers a clue. It shows how large oilfield manufacturing is relative to other sectors, specifically automotive and aerospace.

In short, relative to cars and planes, making oilfield components is not a large activity. And yet, even in the graph above, the potential effect of a surge in oilfield manufacturing can be seen. Oilfield work has the potential to go from a sliver of the pie that is minuscule overall, to a sliver that—while still small—is large enough to be seen within the pie as a whole.

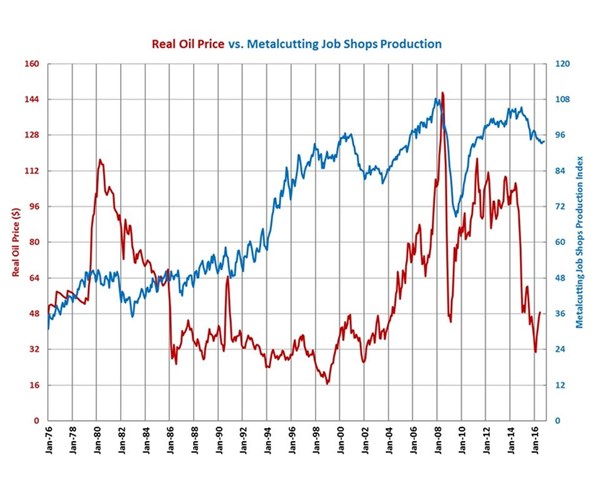

This final graph perhaps illustrates that. Here is the price of oil compared not to oilfield equipment production, but to metalcutting job shop production overall, including production serving automotive, aerospace and everything else. A correlation here is not visibly clear. Statistically, the correlation is 60 percent. That smaller amount of correlation might pick up the domestic oil sector’s impact on manufacturing more broadly. In particular, note that in the most recent years, this graph of metalcutting in total actually shows the same pattern as the graph above for oilfield producers. That is, in the most recent years, as oil price rises or falls, metalcutting activity as a whole soon also does the same thing:

That effect—if it is real and if it is causal (two big “ifs”!)—lends credence to the case that an oil price that is higher than it is now is not as negative a development as we once might have seen it to be.

That is far cry from saying we should root for oil price to rise. It is still true that higher fuel costs would make U.S. residents’ lives more expensive. But as oil production contributes more to the success of U.S. industry over time, the downside of oil price increases gets smaller. When the day comes that the United States is a net exporter of oil products, we might, indeed, find ourselves rooting for more expensive oil.

Read Next

Shop Tour Video: You've Never Seen a Manufacturing Facility Like This

In the latest installment of our “View From My Shop” series, explore Marathon Precision’s multi-process approach to manufacturing, where blacksmiths and hand-forged dies meet state-of-the-art CNC machining. Discover how restoring classic muscle cars and building custom art projects creates a dynamic shop culture — and draws top talent to this unique and innovative metalworking facility.

Read MoreWhy We Ask Machine Shop Leaders to Speak at TASC – The Automated Shop Conference

TASC is our industry’s premier peer-to-peer automation stage where America’s shop leaders refine the art of metalworking and CNC machining. For conference speakers, it's also an opportunity to showcase your skills and gain exposure for your business. Here are five why stepping into the spotlight at TASC could be your smartest move toward elevating your shop.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More