Hydraulic or Pneumatic Actuation for Collet Blocks?

Collet-style workholding devices like collet blocks offer a number of benefits, but which actuating method is most appropriate for you?

Share

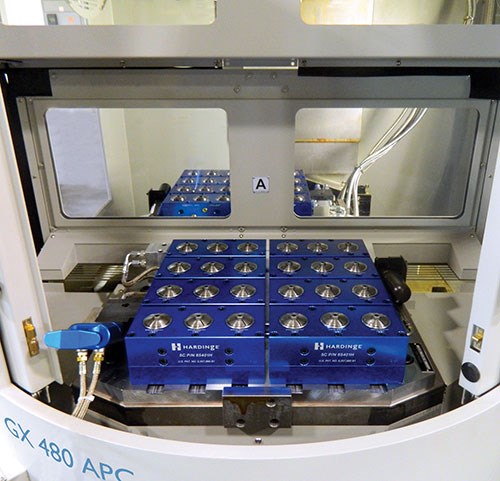

Grouping collet blocks together enables machine tools to machine multiple parts unattended. Collet blocks can be configured in a number of ways, including on tombstones and trunnion tables.

Collet-style workholding devices, such as collet blocks, offer a number of benefits. Collets automatically center parts to their center points known locations, they provide equal gripping pressure around a part’s circumference and expanding collet systems enable effective internal gripping of thin-wall parts. Grouping collet blocks together enables machine tools to machine multiple workpieces unattended over long stretches of time. However, should you go with pneumatics or hydraulics to actuate them? This article based on input from offers advice.

Related Content

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.