Articles

Automation For Chucked Parts

A free-standing parts loading system allows automated material delivery and parts storage so a chucker can run unattended for long stretches of time.

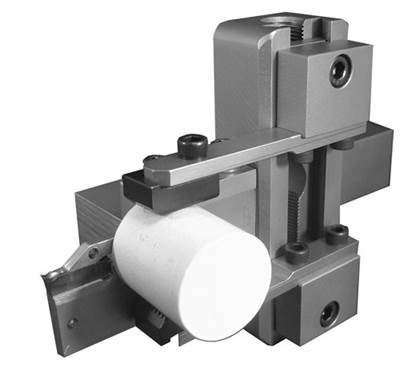

Read MoreOne Tool, Two Turning Functions

A combination bar puller and cutoff tool is an inexpensive way to enable short stretches of unattended turning while saving a turret position.

Read MoreA New Spin On Parts Collection

How do you manage the parts your bar-fed lathe creates overnight? An indexing collection device can serve as an effective means to safely collect precision components.

Read MoreFire Safety First

Don’t overlook safety when considering running your lathe unattended. An on-machine fire suppression system can save not only your lathe, but also your facility.

Read MoreA Different Type Of Twin-Turret Lathe

The vertical-bed design used on this twin-turret lathe offers accuracy advantages for turning shafts.

Read MoreReplacing Turning with Grinding

This compressor maker’s custom impeller profiles used to present a sticky machining problem. Now, the parts no longer need the wax that turning used to require.

Read MoreSharing The Big Picture

The theme of visibility in manufacturing finds expression in numerous ways at this shop. One of the most conspicuous is the use of plasma displays in strategic areas to summarize the company’s performance as reported by its shop control/data-collection system.

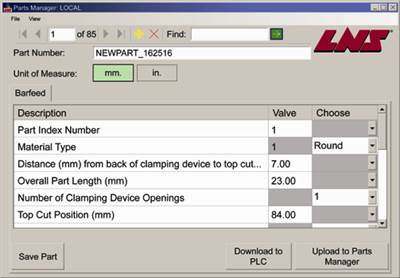

Read MoreLathe and Feeder Talk Via Ethernet Interface

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

Read MoreWaterjet Cutting a Titanium Golf Club

Here is a different way to think about the slice in your golf game. This footage comes from a Web site exploring the lighter side of waterjet machining.

WatchThe Basics Of Producing Big Parts

This Florence, Kentucky-based machine tool builder uses its own equipment to produce machine tools. Here’s how they succeed at big-part machining on a large five-axis machining center.

Read MoreFrictionless Machining Reduces Heat, Chatter

Friction resulting from moving machine components rubbing together can create vibration and heat buildup, both of which can cause problems during machining operations. One machine from NTC America uses hydrostatic components to eliminate sources of friction for high-precision, small-parts machining.

Read MoreA New Spin On Vertical Grinding

Simultaneous, dual-wheel vertical grinding offers advantages for finishing bearing surfaces and other critical features on shafts. Having two opposing grinding wheels in contact with the workpiece at the same time neutralizes axial forces and shortens cycle times.

Read More