Articles

Selecting The Right Welder

Many machine shops, on occasion, have a need for welding. It may be for maintenance purposes, repair or to fill the odd contract. This story is a welding process primer for those shops whose main business isn't welding but need to know some basics.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreMetalworking Growth Posts Another Month of Steady Slowing

All components of metalworking activity in July 2022 contributed to the slowdown in what has become a consistent pattern the past few months.

Read More91ÊÓƵÍøÕ¾ÎÛ: August Edition

The August issue of 91ÊÓƵÍøÕ¾ÎÛ is out now! Check out this month's edition and subscribe to keep up with the latest from around the industry.

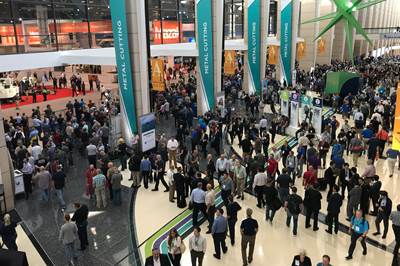

Read More5 Tips for Getting the Most From the Historic Return of North America’s Biggest Manufacturing Event

Plan. Explore. Think of the future. And oh yeah, the shoes. Here is how to get the most from the major manufacturing event that none of us have experienced in four years, and that many will be experiencing for the first time.

Read MoreSensitive and Strong: Advanced Digital Comparators

Borrowing from cell phone touchscreen technology, user interfaces on industrial gages are increasingly sensitive — and strong.

Read MoreSolving Holemaking Issues: Boring or Reaming?

Single-point boring and reaming are both excellent ways to meet high tolerances and finish requirements for hole making, but each has distinct specialties.

Read MoreA Show That Bucks the Status Quo

IMTS 2022 - The International Manufacturing Technology Show will feature more than the latest metalworking technologies. It will provide a strong case to American manufacturers that now is the time to bring production back home to the United States.

Read MoreBuilding a 5-Axis Cell

5-axis machining has taken over the metalworking industry, but what goes into a high-functioning 5-axis machining cell?

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

WatchGrinding Simulation Enables Growth in Custom Tooling

Simulation software both streamlines Gorilla Mill's grinding machine setups and speeds up the company's tooling design and verification processes.

Read MoreWhen To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

Read More