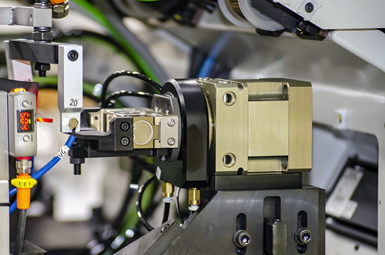

Machine Demo: MW35 with iFLiPP - Faster Functionality Meets Furious Productivity

MW35's lightning-fast loading and unloading pace of three seconds is enhanced by the patented iFLiPP automated orientation feature, eliminating changeovers and machine downtime. (Sponsored)

Share

Muratec Machinery USA's MW35 twin-spindle machine with pick and place iFLiPP loading system enables quick materials loading for continuous operation and mass production. MW35's lightning-fast loading and unloading pace of three seconds is enhanced by the patented iFLiPP automated orientation feature, which feeds the workpiece into its swing arm—either head-leading or head-trailing—in 1.9 seconds, eliminating changeovers and machine downtime.

Muratec will be at IMTS in the south building, level three, in booth #338844.

Related Content

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.