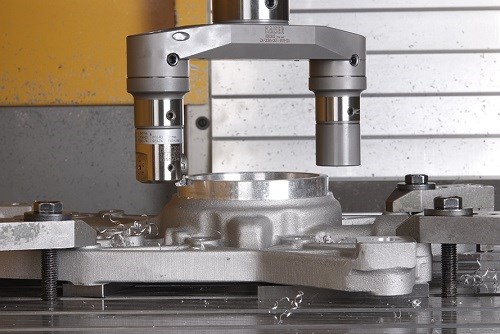

OD Turning on a Machining Center

A tool like the one seen here can make it possible to machine precise cylindrical features of an otherwise odd-shaped part to a fine finish without resorting to a lathe.

Share

You probably didn’t know how effective your machining center could be at OD turning. A tool like the one seen here can make it possible to machine precise cylindrical features of an otherwise odd-shaped part without resorting to a lathe, and doing so in a way that achieves finishes superior to what circular milling can achieve. The tool shown here is supplied by Big Kaiser, which prepared on the various tooling types that might be used for OD turning on a machining center.

Related Content

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.