Examining Productivity Gains Set to Transform Additive Manufacturing

Additive manufacturing is in its second hype cycle, with companies weighing its endless design capabilities against cost and production output.

Share

If you are familiar with the Gartner Hype Cycle, you know that every new innovation undergoes a period of excitement that eventually crashes when expectations have outpaced what the technology can really do. As this happens, the new technology moves from the “peak of inflated expectations” into the “trough of disillusionment”, which is often where many new technologies wallow and die. If, however, a technology continues to develop and meet expectations, then it can crawl out of this low point and up the “slope of enlightenment” to gain solid footing in the “plateau of productivity” where the technology finally achieves more realistic expectations.

Additive manufacturing (AM) has been undergoing this hype cycle for over a decade now. In fact, I think we are in AM’s second hype cycle with the first being in the early 1990s when 3D printing found thanks to 3D Systems. The hype of what polymer 3D printing could do back then quickly exceeded the reality of what it was capable of, and many lost interest in the technology once the “” had been solved.

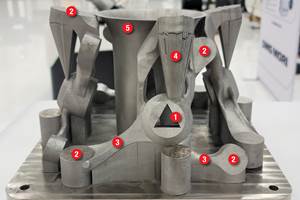

As the era of metal 3D printing dawned in the early 2010s, we entered a new hype cycle under the guise of additive manufacturing, which enabled layer-wise fabrication of functional metal parts and end-use components. To change the perception, 3D printing was rebranded as AM to indicate that it could now compete with , such as subtractive and formative processes, to produce end-use parts.

As with any new technology, though, the hype again outpaced the reality, especially in terms of cost. Part of this was rooted in the lack of understanding that we had about metal AM processes like powder bed fusion and directed energy deposition, increasing uncertainty and risk of use and adoption. We simply did not have hundreds or thousands of years of experience with AM like we did with subtractive and forming processes, respectively, and no one wanted to repeat the mistakes that set back other manufacturing innovations.

As if the added risks were not enough, the economics of AM exacerbated the problem. The hype was driven by what I and a colleague dubbed “” in manufacturing, namely, the ability to produce customized or tailored parts on demand via increasingly small lot sizes at a reasonable cost. The financial benefits arose from the unique . While things looked good on paper, in reality, the costs of machines (and subsequent build time of a part), metallic powder feedstock and postprocessing that few AM business cases made sense.

Thankfully, some companies were not deterred, particularly in the aerospace and medical industries where weight savings and geometric complexity were easily translated into added value worth the extra cost, and particularly with expensive materials like titanium. Meanwhile, the defense industry pursued AM as a solution to improve logistics and sustainment of legacy systems in its aging fleets. Combined, this incentivized federal and corporate investments that led to the development of new standards, reductions in material costs, and improvements in machine reliability and throughput, allowing more and more companies to climb the “slope of enlightenment” and reach the hallowed “plateau of productivity.”

A fleet of 100-kW powder bed fusion systems, each with an array of 150 lasers, that can deliver up to 2 MW of power during production is enabling VulcanForms to produce metal AM parts faster at substantially lower costs compared to what companies can do using commercially available AM systems. Photo Credit: Suzanne Pinto, VulcanForms

Achieving this plateau is also getting easier thanks to advancements in multi-laser systems such as Velo3D’s and SLM Solutions’ . Even though , it does improve throughput and reduce lead-time. Increase that to 150 lasers delivering 100 kW of power like VulcanForms has recently announced, and you begin to see entirely new plateaus of productivity that were previously unobtainable. (Full disclosure, I advise VulcanForms and have received a small equity stake for my help.)

While VulcanForms may seem like just another step in the ongoing “laser wars” of powder bed fusion providers, it is actually the first time a company is not focused on making better AM systems to sell to other companies to make AM parts. Instead, VulcanForms is making better AM systems to make cheaper and faster AM parts. It is worth repeating: their goal is not to produce better and faster AM systems; their goal is to produce AM parts faster and cheaper.

At first blush, this may not sound much different, but in reality, it completely changes your mindset when your entire business is built on producing AM parts, not selling AM machines. It reminds me of when Henry Ford realized the productivity gains that could be made when the parts moved to the workers via the assembly line versus the workers moving to the parts. This too may not have seemed like much of a shift at the time, but as more and more capabilities were vertically integrated, a new plateau of productivity was achieved, giving birth to mass production and the industrial revolution of the 20th Century.

Only time will tell if the shift in thinking by VulcanForms will usher in the AM boom like Ford did with the moving assembly line, but productivity is certainly shifting to a new plateau — and machining professionals should pay attention, lest you become the next acquisition target!

Related Content

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreLast Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ĘÓƵÍřŐľÎŰ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ĘÓƵÍřŐľÎŰ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More