Study Details Advantages of MQL for Micromachining

A recent study found that Minimum Quantity Lubrication increased tool life by 100 times versus dry micromachining of 316L stainless steel.

Share

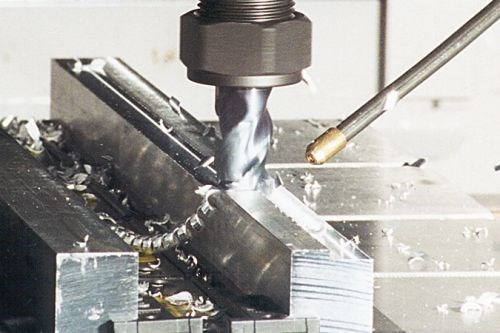

MQL minimizes a shop’s environmental impact by significantly reducing fluid usage and eliminating the need for coolant treatment and disposal.

In a recent e-newsletter, Unist, designer and manufacturer of industrial fluid application systems, cited a study about micromilling 316L stainless steel using Minimum Quantity Lubrication. (MQL is the process of applying minute amounts of lubricant directly to the cutting tool/work piece interface instead of using traditional flood coolants.) The study found that a properly configured MQL process can reduce the built-up edge on a micro cutting tool and increase tool life as much as 100 times compared to dry milling. It cites the importance of quantifying tool runout, wetting both the cutting tool and the workpiece, and properly positioning the MQL stream to maximize lubrication at the chip/material interface.

The report (“Micromilling in Minimum Quantity Lubrication” found in Machining Science and Technology: An International Journal) is available for purchase . Additional information about the advantages of machining with MQL can be found at as well as this blog post and this article about Ford’s use of MQL.

Related Content

-

Jorgensen Introduces Sustainable Conveyor, Material Handling, Coolant, Filtration Solutions

IMTS 2024: Jorgensen Conveyer and Filtration Solutions announces a lineup for conveyor, material handling, coolant and filtration solutions, including the EcoFilter80 self-cleaning system, the PermaClean system and others.

-

Master Fluid Solutions Semisynthetic Coolant Inhibits Corrosion

Trim MicroSol 685XT is designed to provide enhanced corrosion inhibition on all ferrous and nonferrous metals.

-

Hennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.