The Basics of Bar Pullers

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. Learn how they work and how shops can benefit from using them.

Share

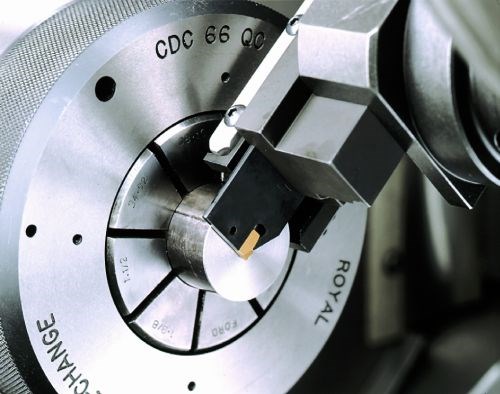

This combination bar pulling unit incorporates a cutoff tool so it occupies only one lathe turret station and eliminates an index from tool to puller.

There are multiple ways to automate a CNC lathe. If your goal is to gain lengthy stretches of unattended operation, then a bar feeder is hard to beat. Conversely, a bar puller is a cost-effective alternative for automated turning of small or medium batch sizes. That’s because a puller can free up sufficient time between bar changes to enable a single operator to tend multiple machines, measure critical part features or perform value-adding secondary operations. The resulting labor cost savings can quickly pay for the puller, as explained in this past article.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.