Trade-offs with AM

Current design tools and process workflow are inadequate to meet our needs.

Share

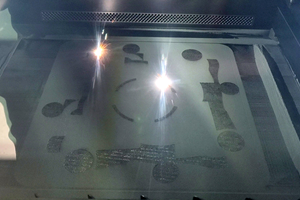

In a previous column, I described how students at Pennsylvania State University designed and produced a lightweight automotive component with intricate geometry using additive manufacturing. The part was built from titanium (Ti-6Al-4V, or Ti64, as it is often referred) on a laser-based powder-bed fusion system in a vertical orientation. The image above shows the part on the build plate inside the machine after fabrication is complete.

What I did not mention about building the part in this orientation was how long it took and at what cost: about 54 hours and about $2,000 in Ti64 powder feedstock. Not bad, one might say, for such a complex part, but consider this: Of the 54 hours it took to manufacture the part, about 30 hours was spent building the supports, while only about 24 hours (44 percent of the build time) was needed to build the part itself. Worse, of the $2,000 in powder, about $1,500 worth was used in the supports; the part itself only required about $500 worth of powder (25 percent of the material cost). This is not so good when you consider that those support structures had to be cut, ground, chiseled and filed away in order for the desired final geometry to be achieved. As a result, more than 75 percent of the powder and 56 percent of the build time went into making scrap. And this doesn’t even take into account the amount of time and effort that was needed to remove all of those support structures, which also added to the production cost. Again, not so good.

The obvious question is why did we build the part this way? The answer is not simple and reflects the limitations of our current design/process workflow and the trade-offs that need to be made when choosing additive manufacturing. First, four different software packages and analysis tools were needed to design that part: CAD software to create the solid geometry, a finite element analysis (FEA) package to analyze the structure, a topology optimization algorithm to help lightweight the component and, finally, software for the build layout and orientation. None of these software packages communicates well with another, and changes made in one are not reflected or updated in the others. So, if we set up the build layout and realize the complexity of the geometry requires too many support structures, we then have to go back and iterate among CAD, FEA and the topology optimization algorithm.

Additionally, build orientation drives build time and powder usage, and these must be traded off with how many parts can fit on a build plate. Multiple parts in different orientations will lead to different heating (and cooling) rates during the build, and this will affect microstructure, which will affect mechanical properties, which will affect the strength of the part, which will affect how it is designed, which means even more iteration. The design tools necessary to analyze all of this and resolve the trade-offs do not even exist yet.

A couple of further points are worth noting related to the cost. First, anyone who has worked with AM knows that $2,000 in Ti64 powder for a build of the size in our example significantly underestimates the cost of the powder feedstock that is really needed. In powder-bed fusion, the entire build volume has to be filled. As a result, you need a cube of Ti64 powder measuring roughly 10 by 10 by 10 inches to make this part, plus some extra to make sure you don’t short the build. The cost for this amount of (virgin) Ti64 powder will run you close to $100,000, much of which can be recycled. Second, supports are generally over-specified. The last thing you want is to have the part warp up from inadequate supports, jam the recoater and cause a build failure. Failures like that get expensive real quick. All the more reason we need better software tools and design/process workflow to make sure we get it right the first time.

Related Content

Digital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read MoreDigitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreThe Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

Read MoreRead Next

Last Chance! 2025 Top Shops Benchmarking Survey Still Open Through April 30

Don’t miss out! 91ÊÓƵÍøÕ¾ÎÛ's Top Shops Benchmarking Survey is still open — but not for long. This is your last chance to a receive free, customized benchmarking report that includes actionable feedback across several shopfloor and business metrics.

Read MoreMachine Shop MBA

Making Chips and 91ÊÓƵÍøÕ¾ÎÛ are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read More