Products

Simulation Software Module Verifies Additive, Hybrid Machining

CGTech has introduced additive manufacturing (AM) simulation capabilities through Vericut software’s Additive module.

Read MoreCost-Effective Milling Cutters Universally Applicable

Walter has added to its range of solid carbide milling cutters with the introduction of its MC232 Perform product line.

Read MoreSmaller Economical Turning Inserts, Holders Maintain Same Performance

Tungaloy is expanding its economical ISO-EcoTurn turning insert and holder system to include VNMG inserts and holders.

Read MoreStandardized Back Boring Tools Available

Steiner Technologies, a provider of back boring tools, has expanded its portfolio with a new reverse machining product line.

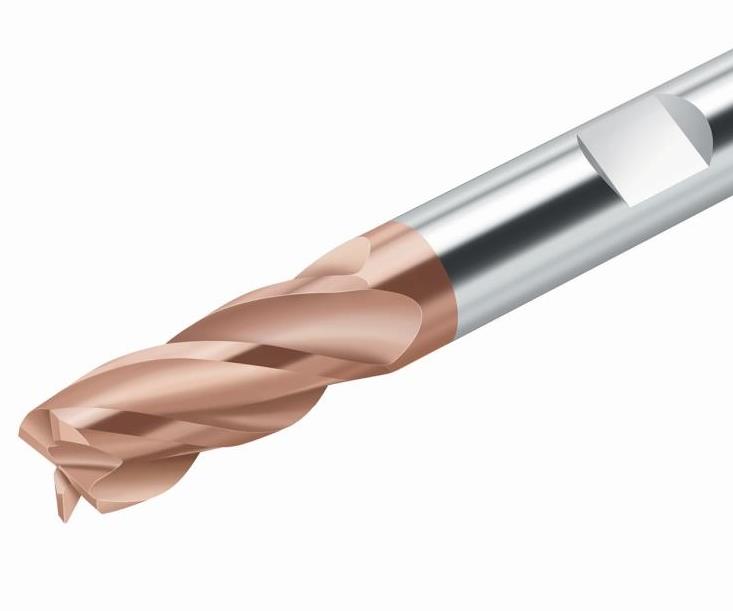

Read MoreEnd Mill for High-Feed Milling in Hardened Steels

Seco Tools has released a new solid carbide end mill designed to boost metal removal rates and extend tool life.

Read MorePrecision Toolholder Lines Get Improvements, Expansions

Schunk’s Tribos-Mini precision toolholder, designed for micro applications, is now available for the HSK-E 20 high-speed spindle interface.

Read MoreInsert Grade Excels in Turning Uneven Forged Surfaces

Sandvik Coromant has introduced its GC4335 insert grade for the turning of steels where unstable conditions or vibration issues prevail.

Read MoreER Clamp Available in More Big Plus Taper

Big Kaiser’s Mega ER grip is designed for high clamping force, concentricity, rigidity and balance at high spindle speeds.

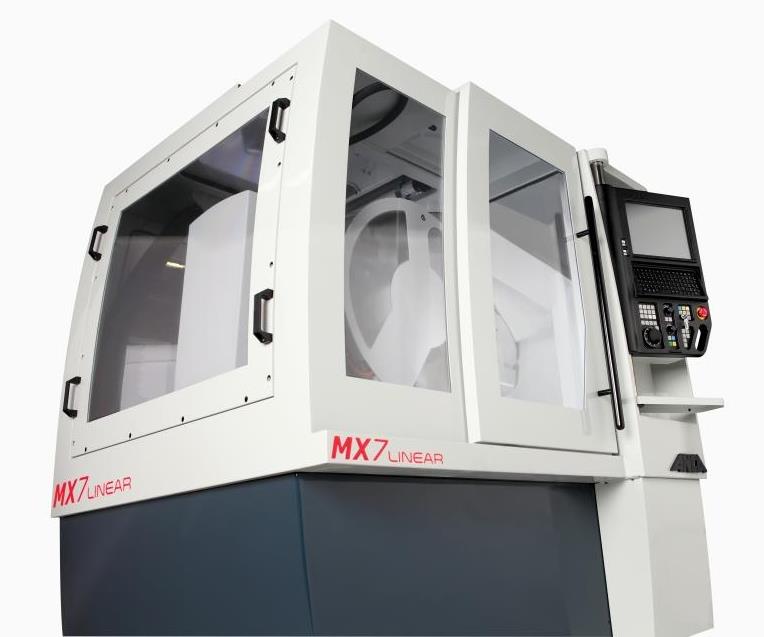

Read MoreLinear Drives Double Productivity of Single-, Twin-Spindle Machining Centers

Chiron’s single and twin-spindle models FZ08 FX and DZ08 FX compact milling centers are now equipped with Chiron’s dynamic precision package.

Read MoreEDM Wire Enables High Cutting Speeds

Sodick has launched JQ (Japan Quality), a new line of EDM wire consumables, consisting of uncoated brass wire that enables high cutting speeds.

Read MoreBrass Coating Protects Carbide EDM Parts from Oxidation

Seibu’s EL coating, available from KGK International, protects carbide parts, resulting in longer tool life and more parts produced.

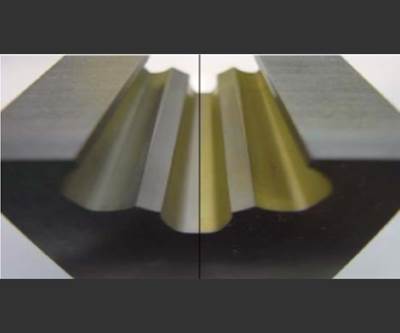

Read MoreLinear Motor Ensures Smooth Axis Movement for Tool Grinders

ANCA Motion’s LinX linear motor technology is designed to provide manufacturers the toolmaking capability to produce highly polished flutes and gash surfaces to improve chip evacuation and aid tool performance.

Read More