CAM-Tool Software Supports Simultaneous Five-Axis Machining

CAM-Tool software, available from CGS North America, features an improved simultaneous five-axis conversion function.

Share

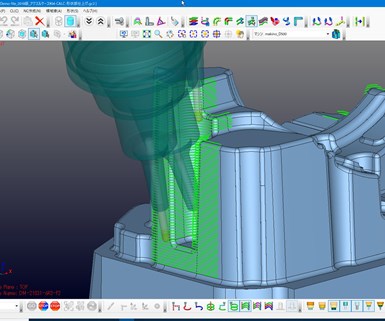

CAM-Tool software, available from CGS North America, features an improved simultaneous five-axis conversion function. The update decreases unnecessary axis movement to provide smoother, more accurate tool paths. The automatic function makes tool paths easier to create, according to the company.

Two tool paths support barrel and lens cutters. 3D Offset Cutting is a finishing mode that outputs offset cutter paths along surfaces with a constant step, while Curve Control Along Surface is designed for control in machining contours and reduced air cutting. Combined with simultaneous five-axis machining, these strategies can reducecycle times and improvesurface finish, the company says.

The system also helps users prepare for five-axis machining by enabling them to display the tool shape against the part model and account for changes in tilt and rotation angle.

Component Point Rearrangement produces smoother machine tool movement for obtaining better surface finishes. The feature arranges component points at equal intervals to optimize tool paths. Rearrangement type can be either Aligned or Alternate.

CAM-Tool’s drilling functions have also been improved. G01 Cross Hole Drilling controls the feed rate when crossing holes, recognizing the crossing section and adjusting accordingly. This adjustment is performed automatically by using the stock model to understand where to apply the strategy. By reducing the feed rate only at the crossing section, the feature avoids chipping that can occur when breaking through cross holes, thereby extending tool life.

Related Content

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.