Hoffman Group Expands Parabolic Performance Cutting Tools

Hoffmann Group USA has expanded its Parabolic Performance Cutting (PPC) series with a set of indexable inserts and Garant PPC solid carbide barrel milling cutters for high-alloy and hardened steels.

Share

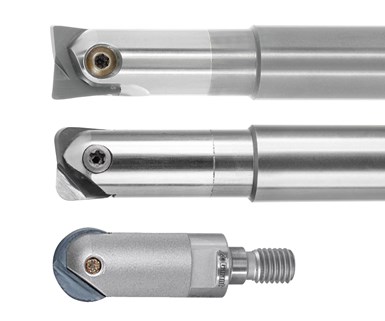

Hoffmann Group USA has expanded its Parabolic Performance Cutting (PPC) series with a set of indexable inserts and Garant PPC solid carbide barrel milling cutters for high-alloy and hardened steels. The PPC process, also known as barrel milling, is a type of ball-nosed slot drill cutting operation primarily used for finishing free-form surfaces.

Compatible with Garant copy milling cutters and tool bodies, the straight or stub point conical inserts are an alternative to PPC solid carbide cutters. According to the company, the PPC cutoff inserts effectively machine flat faces and freely accessible surfaces without interference contours in steel, high-alloy and hardened steels, stainless steel, and aluminum.

In addition to the new PPC indexable insert, the Hoffmann Group has optimized three versions of its PPC solid carbide barrel milling cutter for hard machining. The new tools have a tangential, conical or stub-point conical form and are also suitable for finishing flat faces and large surfaces with interference contours, as well as deep and hard-to-access cavities.

Related Content

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.