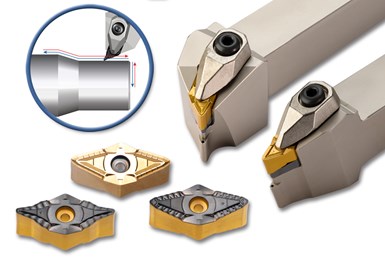

Ingersoll Introduces Superturnz Inserts

Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert, is now available from Ingersoll.

Share

Ingersoll now offers Superturnz, a multi-directional turning system that uses the front and back cutting edge of a four-corner insert. According to the company, it is an alternative to conventional turning, where 80- and 35-degree corner inserts are fed in the same direction.

Superturnz uses all four directions available on a conventional two-axis lathe (+Z, -Z, +X and -X) to maximize material removal. The double-sided positive SuperTurnZ inserts have the same axial and radial rake angle and capability as standard ISO positive inserts, allowing for low cutting forces, but with additional cutting edges and higher feed rate capabilities, according to Ingersoll.

Related Content

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

High-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

.JPG;width=70;height=70;mode=crop)